With the increasing trend toward the use of fiber instead of co-ax cable in a wide range of applications, most contractors are now required to understand the basics of terminating and laying fiber optic cable.

Contrary to its reputation, fiber is actually quite easy to handle and use.

Cable Construction

Fiber, at its most basic level, is a very pure strand of glass through which light can pass over great distances. All fiber optic cable has at its center a fiber core made of such glass, which is used for the actual signal transmission.

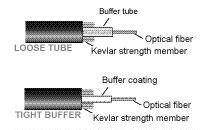

The two most common techniques for protecting the fragile fiber are enclosing it in a loose-fitting tube and coating it with a tight-fitting buffer.

In the loose-tube method, the fiber is enclosed in a plastic buffer-tube that is larger in inner diameter than the outer diameter of the fiber itself.

This tube is sometimes filled with a silicone gel to prevent the buildup of moisture. Since the fiber is basically free to “float” within the tube, mechanical forces acting on the outside of the cable do not usually reach the fiber.

In the tight buffer construction, a thick coating of a plastic-type material is applied directly to the outside of the fiber itself.

This results in a smaller diameter of the entire cable and one that is more resistant to crushing and impact. However, because the fiber is not free to “float”, its tensile strength is not as great.

Tight buffer cable is generally lighter and more flexible than loose-tube cable and is usually employed for less severe applications such as within a building or between individual pieces of equipment.

Like copper wire, fiber optic cable is available in many varieties. There are single and multiple conductor constructions, aerial and direct burial styles, plenum and riser cables and even ultra-rugged military-type tactical cables that will withstand severe mechanical abuse. The cable one chooses is, of course, dependent upon the application.

Both loose tube and tight-buffer constructed cables are available in single-mode and multimode versions. These terms refer to the diameter of actual glass fiber located within the core of the cable. More specifically, they refer to the number of light paths that may pass through the fiber.

Single-mode fiber is so thin (8 to 10 microns, diameter) that only a single path of light can pass through its length. By contrast, multimode fiber, 65 microns in diameter, allows multiple paths of light to travel along its length simultaneously. Although it may seem counter-intuitive, single-mode fiber is able to carry more information over farther distances than multimode fiber.