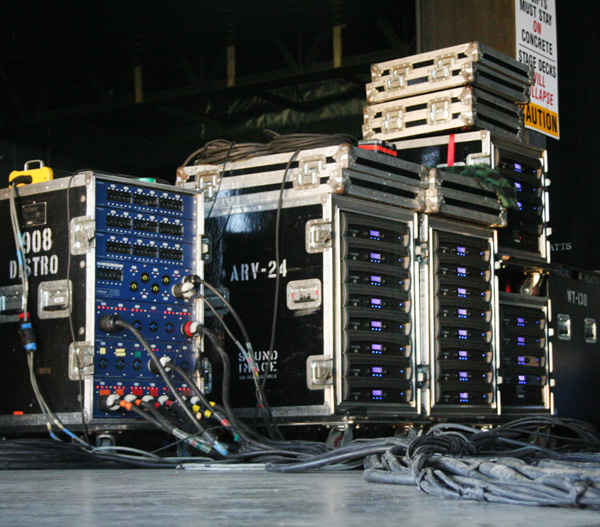

Portable protected and shock absorbing racks provide the most protection to equipment and should be used in all demanding applications, such as for rental and touring systems and for delicate or expensive equipment.

These racks come in three configurations: an inner sleeve and outer bonnet assembly; a shock mounted inner sleeve; and isolator mounted equipment rails.

The most popular with touring sound companies is the inner sleeve and outer bonnet assembly.

Inner Sleeve & Outer Bonnet

The inner sleeve is a self-contained rack with sides, a top, a bottom, and equipment and accessory mounting rails at the front and rear. Most are constructed of 3/4-inch (19-mm) plywood, although some designs consist of a tubular steel frame with side panels.

Typically the electronic equipment is mounted in the front, and the input, output, power, fan and other panels are mounted in the rear. All are recessed into the sleeve for added protection. The sleeve sits on a shallow dolly when in use. To transport the system, the bonnet is slipped over the sleeve and secured to the dolly, completely enclosing the sleeve.

The bonnet is held in place with recessed or surface mounted latches. The casters are mounted to plywood runners which then mount to the rack. This distributes the weight and captivates the carriage bolts between the plywood and the rack, making caster replacement easier.

The carrying handles should be located at 20 inches (508 mm) above the floor for easy lifting and should be on the sides; when the rack is tipped off the casters for shipping it will be resting on the front or rear, putting the electronics in a preferred position.

The inside of the bonnet and dolly are lined with foam and this provides the shock isolation to the sleeve. It is necessary to select a density of foam which will compress during impacts. The force of the impact on the foam depends on both the weight and the surface area the impact is applied to. Even a very soft foam will not compress if the force is spread over a large area.

For this reason it is best to line only the corners of the bonnet and dolly and to use a dense foam. The bonnet and dolly are generally constructed of 1/4-inch to 3/4-inch (6- to 19-mm) plywood which may have a thin bonded outer covering of fiberglass or of metal such as aluminum. The joints are reinforced with aluminum and the corners with metal caps.

Shock Mounted Inner Sleeve

A second type of shock absorbing rack, similar in principle to the bonnet type and built using the same techniques, is achieved by mounting a sleeve or metal frame inside a protecting outer rack, with removable front and rear doors.

The inner rack is suspended on rubber, spring, or foam isolation. Removing the doors exposes the inner rack.

This approach has advantages in use over the bonnet type although it is more difficult and expensive to build well. If foam is used in the outer rack and the sleeve slipped inside, the doors must be lined with a dense foam around the perimeter so that if the rack is transported face up or down and slips, the edge of the sleeve, not the equipment, rests on foam.

Rubber and spring isolators are difficult to install and maintain compared with foam, although when properly fitted they will not allow the inner sleeve to slide against the doors.