Important lessons can often be learned while doing humble tasks — lessons that can later apply to everything else in your life.

So it was with my 19 year-old son Alan’s Honda Civic.

He had received it the year before, and while it ran pretty well, there was a nagging engine miss at idle.

He pretty much worked around it, slipping the automatic transmission into Neutral at stoplights so it wouldn’t shake itself to pieces.

But, we both knew something was wrong, and the longer we waited, the worse it was going to get.

I was a good mechanic when I was a kid, so after buying a compression gauge we tested the cylinders and found #3 to be at 40 PSI (pounds per square inch), not the 140 PSI of the others.

I pretty much knew what that meant, given the put-put sound from the tailpipe — a burnt exhaust valve.

I also knew that the $15 part was going to be a bear to install. You need to drain the coolant, pull the head, yank the valve(s), lap the valve seats and install new valves.

Then you’ve got to clean up the gasket surfaces, remount the head, torque everything up properly, put in new antifreeze and start it up.

I was a little apprehensive about doing this in the driveway since it had been 30 years since I had my hands that far inside an engine. But when confronted with the local garage estimate of $1,500, we decided it was worth the time and effort.

Still, I really didn’t think Alan was going to stick with the project and I would be left doing the entire job myself. Not a happy idea, since I knew all too well the most tedious part of the whole thing: cleaning off the old head gasket.

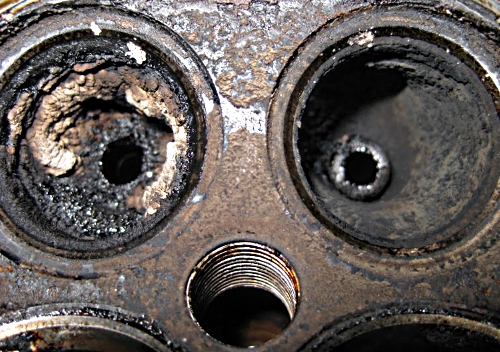

Yes, cleaning the old head gasket seems like a simple thing until you realize it was glued onto the aluminum head 20 years ago at the factory, and if you scrape too hard you’ll scratch the head.

Scrape too little, and just one bit of gasket left behind would ruin the job, forcing you to pull the head and start all over or the engine would blow up. Not a fun thing to have happen.

So after the head was off and we were looking at the greasy mess I gave Alan the job of scraping and cleaning off the head gasket. When he first started scraping there was some complaining.

After all, there were video games to play, and Guitar Hero was a constant pull. As each hour went by he kept asking how much longer it would take.

I could only say, “until it’s done.”

So, as I would inspect his cleaning job I would describe what a good head cleaning job looked like.

“It should look like smooth silver,” I would say.

And he would have me look at that dirty, grimy head and ask again if it was good enough. I would say, “No, let’s break for lunch and start at it again in an hour.”

Later that afternoon it was closer to clean, but still not good enough to my eye. He considered slapping it back together with old gasket material stuck to the head.

Even his twin brothers asked “Isn’t it good enough?” And I would say, “No, it has to be as perfect as you can make it. Anything less will fail.” Now while Alan was scraping and buffing the head, I was doing the same thing to the opposite mating surface on the engine block.

I had the advantage because I had worked in a truck garage as a 16 year-old scraping gaskets. So when he looked at the job I had done at my half of the project, he got all excited. “So my surface should look like that?” he asked looking at my shiny silver gasket area.

I said, “Yes, it has to be that good or it will fail.” He redoubled his efforts and soon had the head gasket mating surface looking brand new.

Sure enough we soon lapped in the new valve, carefully assembled the head, torqued the bolts in sequence and put in the antifreeze. He turned the key and it started right up.

Alan seemed a bit surprised that it started since there had been so many steps involved. But I assured him that the success of the project was in a large part due to the time he put into cleaning parts.

What seemed like the lowliest of jobs, one that no one else would ever see, was, in fact, one of the most important jobs. Without his effort of cleaning the head as perfectly as possible, the job would never have been done properly and the engine would have blown up soon after starting.

I see this same sloppy attitude many times with sound and praise teams in the worship environment. Musicians won’t tune their instruments, sound teams show up late and the music and message of the Worship service suffer as a result.

After all, who cares if the cables are wrapped properly, the connections all labeled and you actually read the instruction manual for your new mixer? If, however, you put in maximum effort with everything you do, shooting for as close to perfection as possible, things just seem to perform better.

This works for your day job at the office, painting a wall in your garage, fixing dinner for your family, even relationships with your significant other.

Do things “just good enough” and you might get by for a while, but down the road failure will crop up. But, put in maximum effort, and suddenly things get better. You feel a sense of accomplishment about what you’ve done, and fewer failures will occur.

Strive for excellence in whatever you do, whether it’s cleaning the cylinder head when replacing a burnt valve, or setting up the sound system with your worship and praise team.

Put in maximum effort. Don’t accept good enough as good enough. Shoot for the moon, as they say. Your efforts will be rewarded.