Heat is one of the biggest enemies of loudspeakers in professional applications in the sound reinforcement industry.

Manufacturers of loudspeaker components must constantly research and develop systems, or technologies, to decrease the temperature of the voice coil.

This then provides the ability to increase the power handling capacity while decreasing the power compression losses, all while ensuring constant SPL responses.

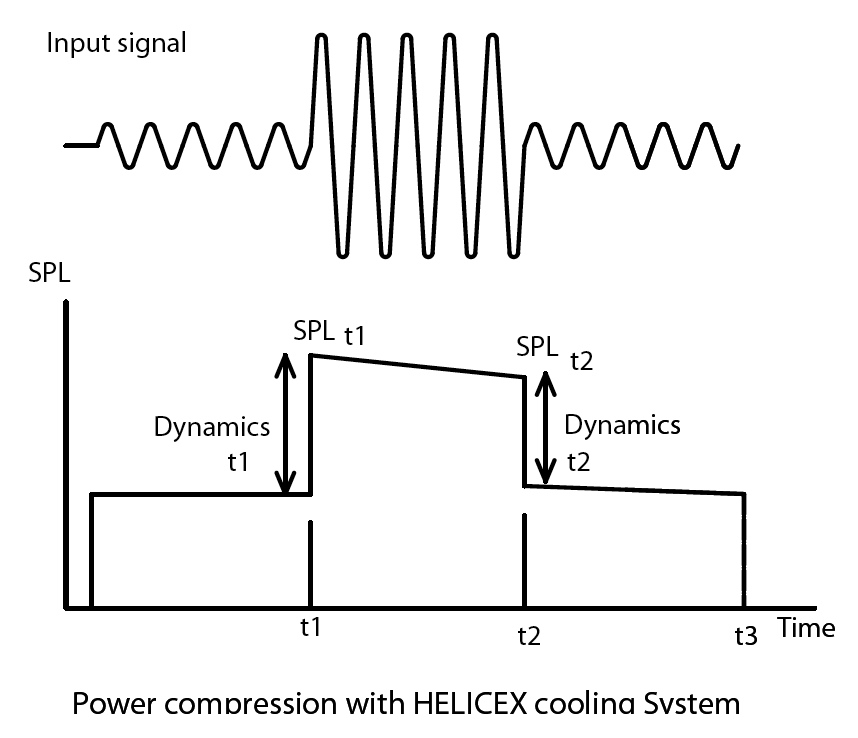

Beyma has introduced its Helicex technology, which offers the advantage of improved dissipation not just in the long term (which is essential), but in the short term, in the way that the SPL losses due to power compression losses are lower (compared to other systems) when there is a sudden increase of power.

This is important since most signals in music are very dynamic.

When an electric signal is applied to the loudspeaker and its level is alternated in short periods of time, there will be a fast temperature increase in the voice coil, and consequently, in the conductor wire resistivity, resulting in a different SPL at the end of the level increase. This causes a lineal distortion in the response.

At the initial input level, the voice coil resistance has changed and the original SPL in not back to the initial level immediately, resulting in a decrease in the dynamics.

Previous and conventional solutions mainly look for increasing the admissible power, but are not always properly focused in this aspect. It has a clear influence in the dynamics in the presence of a lineal distortion.

Beyma’s Helicex system provides a solution that tries to decrease those variations, apart from the global power capacity increase, avoids a significant temperature fluctuation, minimizing the dynamics variations and maximizing the SPL at every opportunity.

The current cooling systems for the voice coil are commonly passive as the voice coil transmits heat by radiation to the other polar pieces, and from the polar pieces to the environment.

An air flux is created in more advanced models, which is in contact with the voicecoil through longitudinal slots in the pole pieces, transferring more heat to the environment by convection.

This is a more efficient system compared to methods many manufacturers employ, but in this case, the forced cooling only partially affects the voice coil surface and the cooling is not complete.

The main advantage of the Helicex system lies in the distribution of its slots, which have a helicoidal shape, allowing the forced airflow to affect the whole surface of the voice coil winding, creating a turbulent mode.

This results in 100 percent of the voice coil being affected by the convection flow. Several tests and measurements made by Beyma have confirmed the improved behavior of the dissipation in these applications.

Jose Martinez and Jorge Serrano both work for Beyma, located in Valencia, Spain.