Sidebar:

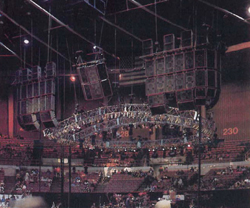

Stress-Testing A Hanging Speaker System

Hanging sound system technology for both touring and installation use can pose some very serious questions. One of these is related to hardware stress, because the methods and equipment chosen to suspend heavy loudspeaker arrays above the ground vary from venue to venue. Portable systems often rely on nylon straps and chain motor hoists, while permanent installations require more solid suspension fittings.

The temporary system places a dynamic or changing load on the rigging hardware. As the speaker array moves up and down, great force can be developed. Permanent installations are usually static, non-moving loads, although some facilities provide for the raising and lowering of arrays.

To ensure the structural integrity of Concert Series enclosures, Stanal Sound commissioned the services of an industrial testing laboratory. “It is imperative to know just what the limits are, and when the breaking point is going to occur ,” explains Mark Engebretson, an electro-acoustical consultant involved in design engineering work on the CS enclosures. “Certification of industrial hardware requires more than guesswork.”

Osborne laboratories, Inc. of Santa Fe Springs, CA, was assigned the task of trying to pull apart one of the new enclosures. With 600,000 pounds of test pressure available, any weak spot in the cabinet’s construction would show up.

A “sacrificial” Model 4870 system was strapped into the firm’s Tinius Olsen model Universal Testing machine, comprising extremely powerful hydraulic screw·cylinders pushing in opposition. Force was gradually applied; the results are shown below.

“The device was calibrated to be accurate within 50 pounds,” recalls Engebretson. “As it turned out, the box was actually stronger than some of the rigging hardware typically used to suspend such speaker systems in the air.”

The series of three ultimate-load destruction tests on the 4870 cabinet were postponed when a nylon strap used to attach the load fasteners separated. A heavy metal clevis was then used in replacement, and the test continued.

“Eventually, the test rig just pulled the box apart,” notes Engebretson. “However, it is impressive that this ultimate failure did not happen on the end-to-end test until a point well past two tons, which is beyond the capacity of the very chain motors that are typically used to support hanging speaker systems.”

Such extreme stress testing is required whenever a hardware manufacturer, or a user of hardware, needs an answer to a very important question: Mow strong is it? Many hanging sound systems use the structure of the loudspeaker cabinets themselves to support the weight of other enclosures. Verifying the structural integrity of an enclosure is one of many required steps along the path that leads to the development of safe, reliable hardware systems.