What’s under the hood?

The front panel of the unit has been kept intentionally simple because most functions are accessed via the Controller software. The front panel does include a push button that identifies the unit on the network and a four-character alphanumeric display that allows the user to both label the unit and scroll status information.

LED’s indicate external control, Ethernet activity and power, while meters indicate signal level, clipping and mute the state. Push buttons mute inputs and outputs, while the front panel Ethernet connection provides local PC access to the processor.

On the back panel, there are the two XLR inputs and six XLR outputs, joined by an RS232 port and two RJ45 Ethernet connectors. The rear panel also includes a three-position groundlift switch that was expressly designed to offer the benefit of transformer-coupled ground isolation while maintaining clean, direct-coupled inputs and outputs.

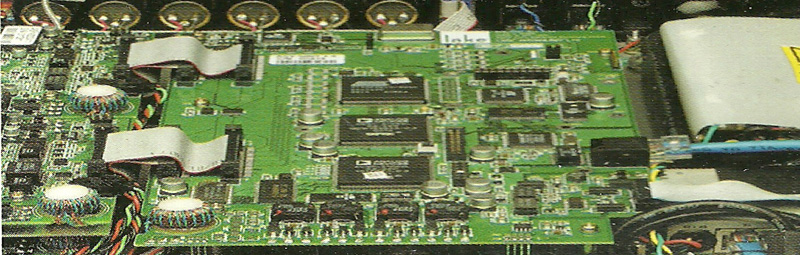

A/D and D/A converters are floating (actually, galvanically isolated) and also are not connected to the main ground. It’s a bit of an elaborate technique that requires high-speed transformers and opto-isolators to create a barrier between the device and any grounding aberrations (i.e., electrical), but it also allows hums and buzzes to be quickly isolated and removed.

While the look and operation of the Contour’s Controller software is decidedly different from normal Windows applications found in pro audio, it does indeed run on Windows (98, 2000, ME and XP) platforms. The software provides the means to adjust Contour’s parameters. A typical setup configures one unit as two modules, each with one input and up to three outputs, to implement either a two or three-way crossover. However, four-way crossovers can also be configured using one Contour unit as a single module.

WIRELESS CONTROL AND OTHER FACETS

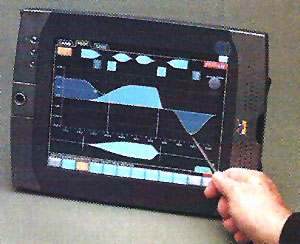

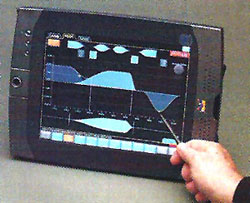

The wireless touch screen that Bruce alluded to earlier is indeed a reality. It allows access to the Controller software while moving to any location in the venue, letting the user listen and adjust any parameter of any Contour processor on the Ethernet network.

Adjustments can be made instantly, providing the responsiveness of an analog system with the benefits afforded by next generation digital signal processing. EQ is accessed by clicking on tabs, labeled by the user that can be engaged or bypassed resulting in easy comparison of EQ settings.

Other Controller adjustments include A/D input headroom, input and output gains, input and output delays, output limiting and output soft-clamp peak limiting. Displayed on the wireless interface screen, high-resolution, fast-updating meters simultaneously show true RMS and peak levels, with peak hold.

Most parameters can be adjusted to within a hundredth of a dB. Fine and course adjustment modes are available, so you can be certain that large adjustments are not accidentally made during a show.

Before focusing on Contour’s unique filtering approach, let’s look at a couple of other notable facets. For example, a “designer” mode has been developed to provide loudspeaker system designers with an optimal base configuration for each type of loudspeaker cabinet.

The base configuration includes an optimized signal flow, front-end EQ, crossover, post-crossover EQ, gain and dynamics, and these settings can also be password protected. In addition, a scrolling menu in the Controller software presents quick access to an available library of base configurations.