The Brute Force Design

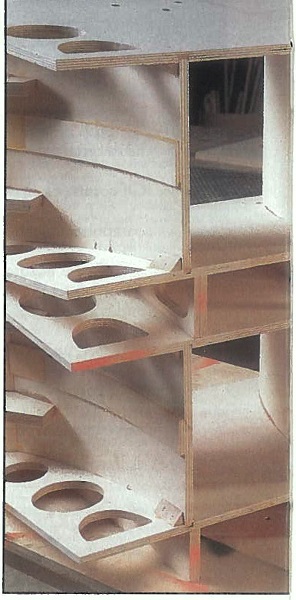

In this approach, large square or rectangular enclosures are constructed from any of several materials. Often, high-grade multi-ply Baltic birch plywood is used, or lesser materials, such as flooring plywood, MDF (medium density fiberboard) and various American plywoods are employed.

In this type of design, the enclosures are usually large, heavy and likely to be rugged. They serve primarily as physical support to the drivers in the mid and high frequencies, and as tuned-reflex enclosures in the low frequencies. Subtleties, such as separate air chambers for low frequency drivers and structurally sound internal rigging points are usually not addressed.

PROS: These are cheap and easy to build. They can occupy a great deal of space and therefore can make a small company look impressive with a 40-box system that is dragged out to every show.

They are basically easy to rig — the square shape lends itself to using wraparound straps or hanging baskets, putting the burden of the rigging requirements on the rigging company instead of the SR company. If the baffle is cut for standard size drivers, any one of a dozen or more drivers may be used, keeping the supplier base flexible. (This can be important when credit limits are reached.) The 90-degree angles readily allow stacking and truck packing.

CONS: The design is archaic at best. There is no inherent ability to form coherent arrays. When used in large numbers, many of these systems fight themselves so badly that alternating vertical or horizontal rows of enclosures must carry separate program material, such as L/R of a stereo mix, in order for the system to produce any useful acoustic addition in the mid and high frequencies.

COMMENTS: Construction techniques make little difference to the final performance capabilities of a large system. Using the finest imported plywood, the best joining techniques, and outfitting the system with the highest performance drivers tuned to perfection, cannot belie the fact that the enclosure is not much more than a tuned box that contains a quantity of drivers.

The resultant devices are not engineered building blocks of a large system; any more than two separate automobiles are able to travel faster than a single one. In small numbers, a good implementation of this sort may perform reasonably well.

However, as the quantities increase, which is typically the case, the lack of arrayability requires large numbers of enclosures to be used to achieve enough power to fill a large length low frequencies will add acoustically, regardless of the specific separation of the individual enclosures, quite possibly producing awesome bass response. But without complementary addition of the mid- and high-frequency drivers, the overall system response will become bass heavy by as much as 30 dB or 40 dB in large systems.

No normal EQ is capable of fixing this much imbalance. The typical approach is to decrease the drive level to the low-frequency amps, producing a step or asymmetrical notch at the crossover point. Users of this system always insist on having the crossover within easy reach.

With the inherent acoustic imbalance, adjusting the crossover is the only way to make the system sound right. However, it is wrong to believe this will fix or compensate for the real problem. It only provides a shadow of a solution. Even several hundred enclosures per side, as impressive as they may be, cannot make up for the interference between adjacent units in the mid and high frequencies.