How can the power loss be minimized?

There are three ways to decrease the power lost in loudspeaker cabling:

First, minimize the resistance of the cabling. Use larger conductors, avoid unnecessary connectors, and make sure that mechanical connections are clean and tight and solder joints are smooth and bright.

Second, minimize the length of the cabling. The resistance of the cable is proportional to its length, so less cable means less resistance to expend those watts.

Place the power amplifier as close as practical to the loudspeaker. (Chances are excellent that the signal loss in the line-level connection to the amplifier input will be negligible.) Don’t use a 50-foot cable for a 20-foot run.

Third, maximize the load impedance. As the load impedance increases it becomes a larger percentage of the total load, which proportionately reduces the amount lost by wiring resistance.

Avoid “daisy-chaining” loudspeakers, because the parallel connection reduces the total load impedance, thus increasing the percentage lost. The ideal situation (for reasons beyond mere power loss is to run a separate pair of conductors to each loudspeaker form the amplifier.

Is the actual performance of the amplifier degraded by long loudspeaker cables?

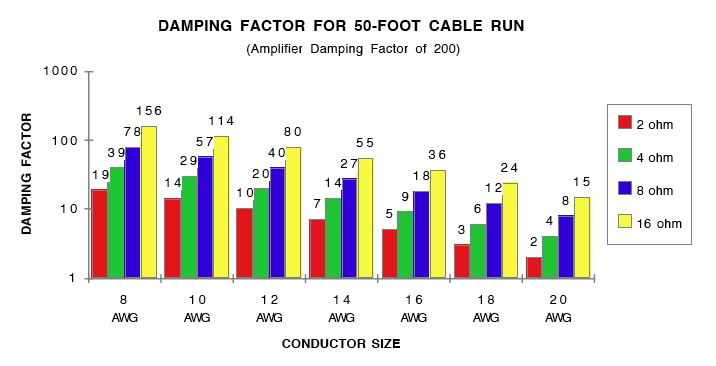

There is a definite impact on the amplifier damping factor caused by cabling resistance/impedance.

Damping, the ability of the amplifier to control the movement of the loudspeaker, is especially noticeable in percussive low-frequency program material like kick drum, bass guitar and tympani.

Clean, “tight” bass is a sign of good damping at work. Boomy, mushy bass is the result of poor damping; the loudspeaker is being set into motion but the amplifier can’t stop it fast enough to accurately track the waveform. Ultimately, poor damping can result in actual oscillation and loudspeaker destruction.

Damping factor is expressed as the quotient of load impedance divided by the amplifier’s actual source impedance.

Ultra-low source impedances on the order of 40 milliohms (that’s less than one-twentieth of an ohm) are common in modern direct-coupled solid-state amplifiers, so damping factors with an 8-ohm load are generally specified in the range of 100-200.

However, those specifications are taken on a test bench, with a noninductive dummy load attached directly to the output terminals. In the real world, the loudspeaker sees the cabling resistance as part of the source impedance, increasing it.

This lowers the damping factor drastically, even when considering only the DC resistance of the cable. If the reactive components that constitute the AC impedance of the cable are considered, the loss of damping is even greater.

Although tube amplifiers generally fall far short of sold-state types in damping performance, their sound can still be improved by the use of larger loudspeaker cables.

Damping even comes into play in the performance of mixing consoles with remote DC power supplies; reducing the length of the cable linking the power supply to the console can noticeably improve the low-frequency performance of the electronics.