Conductivity

While copper has a certain amount of resistance to signal flow, steel and aluminum have significantly more. This resistance dissipates in the form of heat. (It’s why steel and aluminum alloys are great for constructing toasters and space heaters but not so great for cables.)

Some cable conductors are made with a combination of aluminum (slightly better than steel) clad in copper. This is a more cost-effective approach and can be effective in meeting conductivity needs, but the more copper (preferably high purity or oxygen-free), the better the conductivity.

The more electrons to move, the larger the conductors must be. This is the overriding reason that an instrument or patch cable shouldn’t be used in place of a loudspeaker cable.

According to the AWG (American Wire Gauge) system, conductor area doubles with each reduction of three in AWG. For example, a 13 AWG conductor has twice the copper of a 16 AWG conductor, while a 10 AWG has twice the copper of a 13 AWG, and so on.

Unlike instrument and microphone cables, which typically carry currents of only a few milliamps (thousandths of an amp) or less, the current to drive a loudspeaker is much higher.

An 8-ohm speaker driven with a 100-watt amplifier will pull about 3.5 amps of current. By comparison, a 600-ohm input driven by a line-level output only pulls less than two milliamps. (0 dB = .775 volts / 600 Ohms = 1.29 mA) (For more about cable gauge, lengths, Ohm’s Law and more, see “Science or Snake Oil?”.)

Shielding

Cable conductors need to be shielded from noise, of which there are two common types. The first is handling noise, in the form of cracking, swishing, scratching, popping, buzzing or humming sounds.

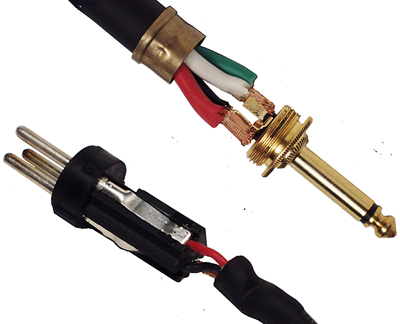

Handling noise can be heard with the cable plugged in but no source audio present. This can be due to substandard electrical termination at the connectors, worn or partially broken center conductor, or inferior wiring in general.

The actual cable construction and the relationship between inner conductors, shielding and outer jacket also affect handling noise.

The second type of noise is interference, of which there are two common types: RFI (radio frequency interference) and EMI (electromagnetic interference).

RFI can be caused by very high radio band frequencies. (You might actually hear a radio station through your system, or high-pitched squeals or hiss.)