Cable selection presents two primary challenges: myriad choices and overall quality. I’ve explored these challenges and have defined six factors that can help point you in the right direction.

These factors include appearance, durability, flexibility, sonics, conductivity and shielding. Let’s have a look.

Appearance

Understand the difference between the look of quality—like shiny gold-plated connector housings—and actual quality construction and materials.

A primary problem arises when assumptions are made that the materials inside a cable housing are as fancy as those that can be easily seen in the connector. For example, molded cable housings can hide poor construction, such as inadequate shielding.

Copper is the most widely used material cable component, offering high conductivity. (Silver is also highly conductive, but cost can make it impractical.) It only makes sense that signal should travel through copper, tip to tip.

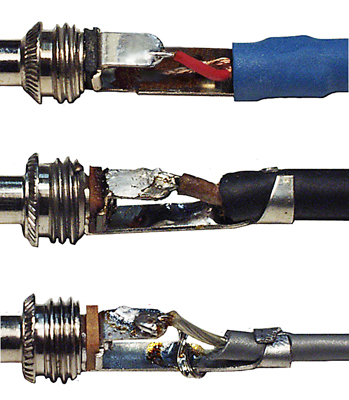

If possible, when evaluating cable, open the connector and check the soldering. Make sure there are no blobs (too much solder) and no contaminates from wire insulation or foreign particles.

The solder should have a smooth slightly shiny surface. A dull solder joint indicates poor workmanship and a poor or non-existent connection (termination).

Other termination methods avoid foreign materials (like solder), which can increase the risk of interfering with signal flow. One process is IDC (insulation displacement connection), done by creating a cradle for the wire in the shape of a “V.” When the wire is inserted into the cradle, it’s pushed to the smallest point of the V, stripping away the cable insulation at the contact points. (This technique does require sturdy strain relief; more on this later.)

A more recent termination method relies upon ultra-sonic welding, a process by which the center conductor and the connector are vibrated together at a high rate of speed while being compressed. This causes them to intermingle and fuse together as one.

Durability & Flexibility

Exposure to temperature, humidity, chemicals, floor traffic and the like can wreak havoc on cables and connectors. Dirt is an extreme abrasive, while foot (and wheel) traffic frequently shred many types of shielding, internal insulation and even the center conductor—sometimes without showing noticeable outer jacket damage.