You see, the National Electrical Code isn’t created by the IEEE, or a consortium of electro-techies.

It is created and published by the National Fire Protection Association, folks with a long history of studying what goes wrong when electricity runs amuck in a building.

Though counter-intuitive, as much if not more emphasis is placed on how a wire burns as opposed to how well it insulates or conducts electricity. This is because much of the code assumes that a fire exists in a building.

A wire that burns with a toxic smoke, when installed in the HVAC plenum, has the potential to release fumes in other areas of a building that may be unaffected by the fire.

As the use of electronic systems and their associated wiring increases, the potential for dangerous smoke propagation becomes a very legitimate concern. Considering that many cables we typically use have rubber or polyvinyl-chloride jackets, it is easy to see the problem.

One sure way to avoid damage to pur wire, contain smoke, limit electromagnetic and radio frequency interference and ease our installation is to use conduit. Though it is not likely that many of us will be installing our own conduit (it’s an art that takes years to master), we are often called upon to tell architects/engineers or electricians what size conduit we require and where it should go.

Because the pipe is a permanent and extremely expensive element of a design, you cannot afford a mistake. If it is too small, you’re stuck; too large and you have :wasted many thousands of dollars that could have been used for cooler gear in the rig (and you look like an ape who can’t add).

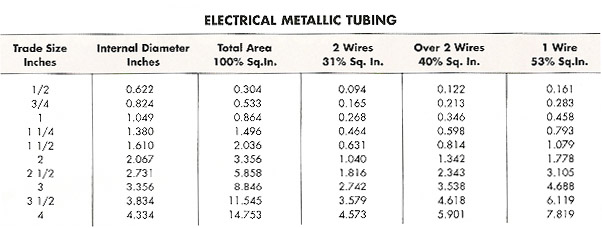

So, how do we size an electrical conduit? First, plan your runs with the understanding that the NEC standard conduit fill is 40 percent for three or more cables. If the pipe is occupied by only one cable, that limit increases to 53 percent, also, because they form a wide oval shape when run together, the NEC only allows 31 percent fill when two wires occupy the same pipe.

As a shortcut, if you have a pipe that is filled with a quantity of the same wire type, this is usually a simple operation. Most wire manufacturers have a chart that lists the standard conduit sizes and their common wire types. Match the column to the row, and you will find the quantity allowed. If you are good with Sudoku, this will be a snap.

If you have various types of wires planned for a given run, assuming three or more wires are in the pipe, a bit of math is required. Of course, you could cheat and use an online calculator, but where’s the fun in that?

Here’s the quick math:

Find the AREA of each wire. To do this, square the nominal outer diameter (NOD) of each wire (listed in the wire specs) and total the results.

Calculate the total area of the wire cross-section: multiply your result by .7854 (this is Pi/4). Select conduit from the chart above (Figure 2).

Cable Diameter Squared = .25 squared = .25 x .25 = .0625

Cross Section Area (1 wire) = .0625 x .7854 = .0491

Total Cross Section Area (12 wires) = .0491 x 12 = .589

An example with 1 wire type – assume 12 wires, with an NOD of .25 inches.

Look at the chart for 40 percent fill and find one that is bigger than the wire … 1 1/4-inch will do the job with room to spare.

Some other tips when planning your conduit runs: Surprisingly, a 40 percent fill is a LOT of wire. If your runs are greater than 50 feet, either reduce the cable counts by 15-20 percent, or use the next size larger conduit.

Also, each 90-degree bend is equal to approximately 30 feet of pulling friction; if you need more than two 90-degree bends to get where you need to go, or that destination is greater than 90 feet set a pull box.

To be certain, we are only doing this install thing because the “real” gig wouldn’t meet our $3,000/day, no-load, no-strike policy. Besides, it was all fly dates, and who wants to deal with that, really? But should you need to make some bucks to help pay for that backwaxing the old lady needs, suck it up and agree to work on that install deal, “just this once.” Just be conscious of your image… black is not the color of choice in apparel, gets hot; boots are required due to foot-impaling pointy things strewn about; shorts are not an option, because you look like a schoolboy, and hardhats are all the rage.

Get used to it… but at least you can be comfortable in the thought that you’ll only have to pull the wire once, the pipes are right, you get to go home at night and payday is always on Friday. Good times indeed.