We’ve already mentioned low-resistance cables, and understand the desire not to waste amp power in heating loudspeaker cables.

There are two problems that work against us when dealing with cable impedance. The power lost in the cable is one factor, but another often overlooked factor is the reduced output from the amp seeing a higher impedance load.

Example 1

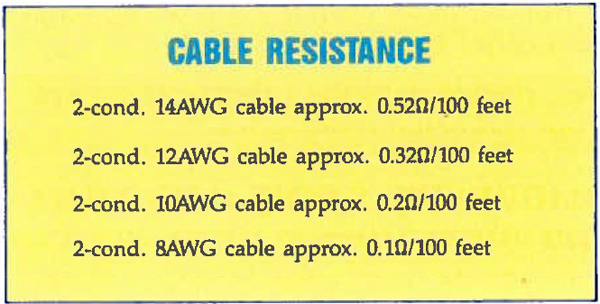

Assume a 1,200-watt (W) amp channel feeding an 8-ohm load using 12AWG cable that’s 50 feet long. Because 2-conductor 12AWG cable represents approximately 0.32 ohms/100 feet, the total load at the amp is 8.16 ohms. Amp output at 8.16 ohms is approximately 1,175W, and the power loss per foot is 0.48W. The total power loss over the 50-foot cable run is 24W, or 0.01 dB. Total power to the load is approximately 1,151W; 49W went away.

Example 2

Assume a 300W amp feeding a 4-ohm load using 14AWG cable that’s 50 feet long. Two conductor 14AWG cable represents approximately 0.52 ohms/100 feet. The total load at the amp is 4.26 ohms, meaning the amp output is approximately 282W, with a power loss per foot of 0.34W. The total power loss over the 50-foot cable is 17W, or 0.27 dB. Total power to the load is approximately 265W; 35W disappeared.

Altec Lansing has a really slick program for calculating these numbers called AMPTOOLS, and it greatly speeds up generating similar data. It also has a dynamite attenuator calculator for designing DA pads. The power loss, even in respectably large cable, can be significant. In the case of daisy-chained parallel loudspeaker hookups, there can be some noticeable differences between the power delivered to the first and last loudspeaker in a chain connected by cables with significant resistance.

Distro Details

Weak links in loudspeaker distribution should be avoided, and there are so many places to build them in, such as the connection to the terminals, the distribution bus and the connector contacts. Measurements of load impedance done at the addition of each stage of the distribution chain can show any negative effects.

The important thing to remember in building a loudspeaker distribution setup is the use of low resistance terminations and connections. Using electrical hardware designed for high current ac hookup is not out of the question when dealing with high power audio circuitry.

It is important to keep cable runs short, not just to avoid wasting power, but to connect some of the amp’s damping factor to the loudspeakers. Damping factor is the ratio of the load impedance divided by the amp’s actual output impedance, not to be confused by minimum load impedance. The low output impedance of an amp is what stops (damps) the loudspeaker from moving when the signal is finished. (Try moving a disconnected loudspeaker cone. Then put a piece of wire across the loudspeaker’s terminals. That’s the nature of damping factor.)

Large amps often have specs that rate damping factors at 1,000, which indicates that the output impedance of the amp is in the range of 0.004 ohms. Tight and clean low frequency reproduction requires a damping factor of 50 or more at the loudspeaker terminals. To achieve that with a 4-ohm loudspeaker requires a total cable resistance in between the amp and the loudspeaker of less than 0.08 ohms. By using the largest wire practical to connect amp outputs to loudspeaker distribution panels, and using really large buses where applicable, you can reduce the overall distribution impedance.

Remember that the resistance of the total distribution cable is always added in series with loads. Once in the circuit, it cannot be ignored. It gets in the way of outbound energy and the ability of the amp to put on the brakes in each loudspeaker. With amps routinely able to drive 2-ohm loads, and some that can drive 1-ohm loads, distribution impedances of even 0.1 ohm are becoming a large percentage of the network impedance.

Safety Counts

The current involved in high-level loudspeaker systems can be substantial. An amp spec sheet off the shelf here tells me that in bridged mono this amp is capable of delivering 2,800W into 4-ohm loads. That’s an audio current of 26.5 amps. In a sound system with a good bit of compression and something like thrash metal for program content, it can probably deliver that at near RMS levels. Anyone who has been “buzzed” off a high-power loudspeaker line can directly appreciate the magnitude of audio output.

The matter of safety has to come into play. With the equivalent of almost 4 horsepower (l hp = approximately 750W) dangling at the end of a loudspeaker cable, it pays to consider it to be a 4 hp lawnmower motor, complete with blade, and treat it with as much respect. Loudspeaker connectors should be capable of dealing with the currents required of them. A phone plug was fine for hooking up your old powered mixers, but serious connectors, such as the Neutrik Speakon and Cannon EP series, are called for in high-power situations. Current handling and short circuit prevention are key elements in connector choice.

Another factor to remember is cable maintenance. As conductors break, often near the connector, the cable resistance will rise. As we have already seen in systems using low load impedances, this will affect system performance. Corrosion of contacts will also play havoc with resistance. A wiping-type contact is a useful feature in a loudspeaker connector.

With a bit of planning and care, signal distribution can be dealt with effectively, providing improvements in signal-to-noise, distortion and reliability.

Barry R. McKinnon is a principal and a senior consultant at McSquared System Design Group in North Vancouver, BC, and has worked in sound contracting and sound reinforcement since 1976.