How are beta partners selected?

Like most partnerships, the prerequisite is mutual understanding and common goals.

The beta test program seems to be quite thorough. What, specifically, have they (beta partners) brought to the table in terms of refining the system? Has any substantive re-design work taken place as a result of the beta partner’s input?

During Beta Phase 1 testing of the loudspeaker system, there have been a few mechanical changes, such as a revision of an aluminum extrusion profile and some packaging tweaks, but more important, is the evolution of filter presets.

Even at the outset of Beta Phase 2, consultation brought on significant changes to the power distribution system that will allow a better fit with companies ranging from small to larger shows.

Let’s focus on the E15: What is the overall scope of this loudspeaker?

To begin, we established a rigorous routine of modeling, finite and boundary element analysis, followed by rapid prototyping and acoustic measurements. This was applied to both transducers and sound chambers.

When combined with our new concept in the physical structure, we achieved the resulting improvements we were looking for.

Simply put, the system comes in a smaller lighter package with more headroom, less distortion and better coverage.

It’s faster to fly than anything on the market and it will offer advanced array processing and intelligent diagnostics.

They’ve been built around what you’re calling an “e-capsule” – can you describe that and offer further insight on the design?

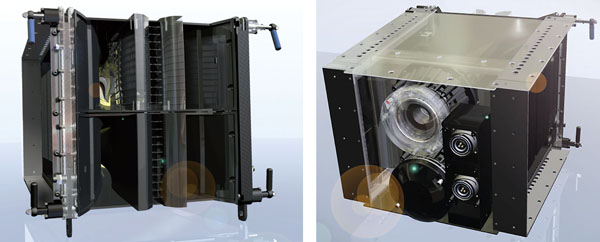

The e-capsule is a rigid aluminum module that houses most of the technology. All rigging, electronics and mid/high waveguides are installed in this capsule. The woofer enclosures are then bolted on to each end. It offers a lightweight solution with the sonic benefits of wooden enclosures on the low and low mid bands. There are a number of patent applications that surround this technology.

How have the loudspeakers been designed to work with the other elements you’re developing – amplification and DSP/networking/interface?

This project is driven by the loudspeakers. The amplifiers have been closely tailored to the loudspeaker requirement, with the entire hardware and software package designed to complement the loudspeaker.

What are the notable technologies, i.e., waveguides, LF chambers, etc?

The core of the E15 is the e-capsule, with the sound chambers and drivers inside. We spent significant time refining sound chamber performance. Our Kevlar cone technology provides great transient response and in turn delivers very high resolution throughout the entire bandwidth.

Were drivers designed specifically for this loudspeaker? What are they, and are there any special aspects to them?

The YX7 midrange driver was designed specifically for this cabinet. This compression driver is more efficient than anything we have built in the past and it has very low distortion as well. As many mix engineers will tell you, most of the details are found in the mid band, and vocal headroom is crucial. This driver is designed to handle this job without question.

Please describe the rigging system and any independent certifications that it carries.

The rigging is designed by Adamson engineers and then reviewed by a German engineering firm. It meets the most rigid standards of BGV C1.

The beauty of the system is that a single technician can set all the angles on the ground before flying it. When it is lowered to the next group of cabinets, it connects automatically. This system has been met with incredible enthusiasm.

Are there other features that enhance the portability (or other usage) of these loudspeakers?

Our dolly allows for three different packs depending on how they are arranged in transport. We wanted to offer a U.S. truck pack, European truck pack and a way to ship safely in a sea container.

Will you be using the beta partner approach with these aspects as well?

The existing beta partners will of course be carrying the flag on the introduction of power. In each phase we will have a period of beta testing. We are cautious and will only integrate the technology in a comfortable way for everyone involved.