PACKING PLENTY

We were also determined that the XLS Series would present a very professional appearance, with the large black grille facilitating excellent flow-through ventilation from front to back.

This is backed up internal heat sinks with forced-air cooling for rapid, uniform heat dissipation.

The front panel is simple and elegant but packs a lot of indicators and adjustment capability. Indicators include LEDs for signal presence -10 dB below clip, -20 dB below clip, clip and thermal.

Each channel has its own rotary level control.

The back-lit LCD screen and three push buttons facilitate configuration of crossover, amplifier mode, and limiter.

Users can step forward and backward through configuration screens with ease.

And, protection for unauthorized or inadvertent adjustment is avoided because a button must be depressed for a full five seconds before the unit allows any adjustments to be made.

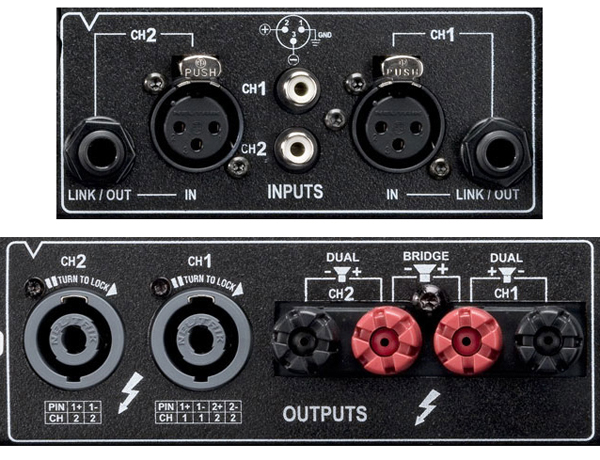

The back panel layout is simple and straightforward, but with plenty of capability. Input connectors include XLR, 1/4- inch, and RCA (all one per channel), and the 1/4-inch connectors can be used as loop-throughs to distribute signal to additional amplifiers.

Above, the input facilities with XLR, 1/4-inch, and RCA (all one per channel). Below, output connectors include Speakon and binding posts that accept banana plugs or bare wire. (click to enlarge)

On the output side, two 4-pole Speakon output connectors accept 2-pole or 4-pole Speakon connectors.

The top Speakon connector is wired for both channels so it can be used for bridge mono wiring or for stereo wiring of two loudspeakers to a single connector.

There’s also a pair of back-panel binding posts per channel that accept banana plugs or bare wire.

The manufacturing process follows practices in Harman Professional’s “Green Edge” initiative. Some of the highlights include a new low-energy powder coat cures at 300 degrees rather than the previous 400 degrees.

The powder coat process uses 80 percent less water than before, and zinc effluent runoff is reduced by 90 percent. All solder is lead free.