Instead of adopting flat wavefronts as advocated by some of the early proponents of touring line arrays, sophisticated in-house BEM (Boundary Element Method) modeling techniques have shown that slightly curved wavefronts deliver much more consistent SPL to the audience where the array is curved – as in most practical, real-world applications.

Placing a kite-shaped “wedge” part-way down the horn enables a specific, desired curvature to be achieved – depending on the shape of this wedge.

In the case of MLA Compact, the HF wavefront is curved to provide a balance between optimal summation over distance and summation at the maximum inter-cabinet splay angle of 10 degrees.

Power & Control

Each MLA Compact has 5-channel Class D amplification, DSP and network electronics that enables the individual cells within each enclosure to be driven with the exact signal determined by DISPLAY 2.1 optimization software for independent control of each of the 24 LF cells, 48 MF cells and 48 HF cells in a 24-box array.

The amplification package provides a total of 2.1kW continuous and 4.2kW peak output. One channel powers both LF drivers in parallel and two channels drive each mid independently. For the HF section, two channels drive the four HF drivers in parallel pairs, making a total of five independently powered acoustic cells per enclosure.

Switched-mode power supplies auto-range to global mains voltages from 100 to 240 volts, 50/60 Hz, while Power Factor Correction smooths out the mains current draw over the whole of the AC waveform. Amplifier monitoring via U-NET includes input signal, output signal at the drive unit terminals, limiter status, heatsink temperatures and driver fault conditions.

Onboard DSP performs all crossover and EQ functions via a combination of IIR and advanced FIR filtering. Fast VanishingPoint FIR filters provide the ability physically separate the MF and HF horns so they do not compromise each other’s constant directivity dispersion pattern, yet achieve the spatial performance of a single device.

Arrays can be remotely controlled over U-NET from a PC or wireless tablet running VU-NET control software with its intuitive graphical interface. VU-NET also enables the user to switch on enclosure identification LEDs with automatic identification of neighboring enclosures and connectivity confirmation.

Dialing It In

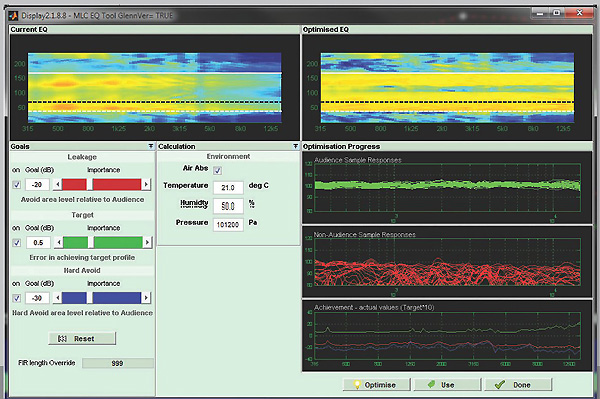

DISPLAY2.1 is the “brain” of MLA Compact, providing a virtual environment within which arrays can be configured and optimized, providing highly accurate prediction of the direct sound produced over the audience and also and over areas where sound is to be avoided. It also bolsters array design and deployment, generating accurate spot frequency responses and comprehensive rigging information, including mechanical load safety analysis.

DISPLAY2.1 interacts with MLA Compact’s onboard DSP to deliver consistent sound throughout a venue. It calculates the filter parameters for each enclosure, down to the resolution of individual drive units, and uploads them to the enclosure via the U-NET digital network. The link between DISPLAY2.1 and an individual MLA Compact enclosure is live and bidirectional.

DISPLAY2.1 reverses the sequence of array design software. Starting with a specified SPL and response over the audience floor, the software works backwards to configure an array that will give the required result.

Since it is a practical impossibility to measure every possible array configuration with different combinations of enclosure numbers, splay angles and drive signals, an accurate acoustic model is essential.

The previously noted BEM (Boundary Element Method) models enable hundreds of virtual array configurations to be investigated in fine detail in a virtual 3D environment. This level of research has transformed our understanding of how arrays really work and shown that the acoustic interactions between array elements are much more complex than originally thought.

An important factor and industry first is the inclusion in the model of the previously ignored effects of adjacent enclosures. If these are not incorporated into the model, prediction errors can be over 8 dB in the midrange. Including the effect of adjacent cabinets is key to the accuracy of the optimization process and increases the accuracy of the acoustic model of MLA Compact.