When I was running a sound company back in the 1990s, I had two hard-and-fast rules that all staff were expected to know and adhere to:

1. Safety was absolutely first. Nothing was to be done in an unsafe manner, ever. And,

2. No action, or inaction, should have a negative impact on a show, ever.

As long as everyone stuck to those two rules, I liked to keep the vibe pretty loose and fun. With that in mind, here are a few humorous incidents from my eight years in that job.

John The Carpenter

When I took over the shop management role in October of ’91, the company was within a couple of years of having absorbed another, smaller company, so the staff was a mixture of “old hands” who I knew from my earlier stint there (February ’81 to December ’84), people who had been hired in the interim, and folks who had come from the smaller company.

John was one of the latter group, so he was an unknown to me. We had fairly minimal interactions in my first few months, other than me informing him that he could no longer smoke in the wood shop (you could still smoke indoors in 1991), because it was … a wood shop and full of combustibles. Over time, I did come to appreciate his work, but first we had to get to know each other…

Sometime in the spring of ’92 I was working on getting my ducks in a row for the busy summer season and realized that I needed to know when I was likely to get my designated lead hand back for the summer. This person was spending his winters doing his doctorate in Film Studies at NYU so I must have met him over the Christmas/New Year’s holiday when he was home and done a few gigs. I knew he was a friend of John’s so I wandered back to the wood shop to see if he knew when we could expect him.

John greeted me with his usual, “Hey chiefy boss guy, what’s up?” This was annoying but I put up with it and asked him if he knew when we would see his friend. For whatever reason, John looked at me suspiciously, with narrowed eyes, and asked me why I wanted to know that?

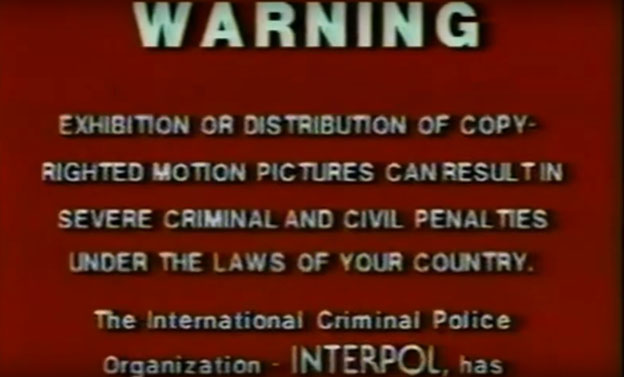

Well, that was not alright in my books, and I gave him a stern look and said his name, quite sharply to … re-set the tone of the conversation. And then, off the top of my head, I added, “INTERPOL is looking for him (the friend).” John reeled back in stunned disbelief and said, “Whaaaat? Why?!!”

Well, his reaction was enough to give me time to think up the next bit, so I added, “You know that warning at the front of the VHS tape of your favorite movie?”

“Yeah…?”

“That!” (Get it? Film Studies = bootlegging blockbuster video tapes…)

“Wow, holy sh*t, that’s serious! I think he’s going to be back around the middle of May!”

I thanked John for the information and told him to keep the INTERPOL thing under his hat. Then on my way back to my office I bumped into the head of the staging department who was a friend of both John and the lead hand (I think the three of them had survived some horrific cross-Canada tour that involved performances in shopping malls and a cube van) and told him what had just transpired in the wood shop. He thanked me and then immediately phoned the friend in New York and told him what was up.

Well, without any further input on my part, those two kept the “hunted by INTERPOL” gag alive for something like the next six months. I can’t recall what finally tipped John off to the fact that it wasn’t true, but until that happened, he was a firm believer.

Another interaction involved a new road case for one of our mixing consoles. When I took over, I discovered that we had exactly one set of multi-pin patch cables for console/rack interfacing. They went with one rig, and everything else involved racks puking cables when you opened the back door. I had experienced this on a show that I did over Christmas ’91 and thought, “This has got to change!”

Flash forward a year and we had standardized on the Whirlwind “W” series connectors (and yes, test driving the first system on the same show in December of ’92, I was burned by a wiring error that was really effectively sealed up inside the rack). Anyway, the new multi-pin system required that our mixer cases have doghouses to fit the patch snakes, so I had to order a new case for our 32-channel Soundcraft Delta.

Of course, the case arrived on the day that the Delta was due to load out for a show, and when we transferred it to the new case, it didn’t quite fit. This then raised the issue of whether we were going to send the case back to our case builder or have John try and fix it (it was a “too much foam” issue, the overall case dimensions were OK).

Now, this whole situation was a bit loaded because of a blow-up I’d had with both John and the case builder a few months earlier. Loading trucks was a real challenge at this company, with the word “Tetris” often being muttered on the loading dock. This was partially due to having almost no standard case sizes, and partly due to the fact that one “standard” was based around some cases that had come from the smaller company.

That company was literally a two-truck operation, with no shop space. So, their gear lived on the trucks … when they got a job, they took whatever they needed out of the truck to do the show, or both trucks if it was a big show. The trucks had custom boxes that must have allowed for four 26-inch cases across, so their “standard” was 26-inch cases. I quickly realized that this was a problem and determined that all new cases would conform to the industry standard 24-inch dimensions.

So, imagine my consternation when the first 24-inch cube case that I had ordered showed up, and it was built to the old 26-inch dimensions! I called the case builder and demanded to know what the hell happened … which turned out to be that he had called John to double check the dimensions (because they didn’t match what he’d built for us before) and John had “confirmed” the old dimensions.

Well, I reamed both of them for going around me to work this out and demanded that this never happen again. So, they were both a little … careful … around me when it came to road cases. Anyway, after several phone calls back-and-forth it was determined that the case builder would give me a bit of a discount on the mixer case because of the error and I would have John (who’s last name began with the letter “V”) sculpt the foam to make the desk fit.

Having resolved this with the case guy, and with John standing by in the wood shop, I picked up the shop all-call and in a moving tribute to the Steven Spielberg classic “E.T” called out “J.V., hone foam!”

On another occasion, I was sitting in my boss’s office, discussing some of the day’s challenges, when John tracked me down. From the hallway, he said, “Hey chiefy boss guy, you got a minute?”

Um … sure? I’m just sitting in the boss’s office talking to him … but sure? Anyway, I responded with, “What’s up John?” and then immediately followed that with “It’s a big pharmaceutical company* but that’s not important now!” That earned me some blank looks from both John and my boss, and now I can’t remember what either conversation was about. (*Upjohn Pharmaceutical)

Actually, on reflection, this happened twice. The second time John said to me, “Hey, chiefy boss guy, you got a sec?” To which I replied, “Well, I’ve had secs…” More blank looks all around…

Where There’s Smoke

One summer day in 1992, we had so much gear out that the shop was literally bare. There wasn’t a single piece of equipment from one wall to the other in the main shop. I was standing in the middle of the shop floor, marveling at this (it was the first time I’d seen it) when our delivery driver came over to touch base.

As I was talking to him about the various jobs that were out and which ones had called in for extras and so on, I began to smell smoke. It smelled like a slow smouldering paper fire, but the challenge was figuring out what could possibly be smouldering in a shop with a concrete floor and cinder-block walls … which had been swept by the morning shop crew. There wasn’t a gum wrapper or a Post-It note to be seen anywhere. We’d been standing in the middle of the floor, but after a minute or so, the driver went over to one wall and said, “I think it smells stronger over here!”

Sure enough, the smell had dissipated where I was standing, and when I got over to where the bare cinder-block wall met the bare concrete floor, the burning smell got stronger, with not one bit of combustible material in sight. After a minute, the driver got bored with the wall and walked back to the middle of the shop floor and announced that it smelled stronger over there again.

This little dance repeated itself a few times before I finally looked down and noticed that the cuff of his jeans was smouldering from where he had inadvertently knocked the lit end of his cigarette…

Oops!

A few years later, we had moved to a much larger shop, and it so happened that on another day when we had a lot of gear out, I got word from the folks in our service department that they were not able to repair the VCR (from my home) that I’d asked them to look at. I said, no problem, I would come and get it out of their shop right away.

On the way back from the tech shop, VCR in my hands, I noticed many of the shop staff doing various odd jobs that don’t get done until the shop empties out. Again, on impulse, I staggered a couple of times and then dropped the VCR on the concrete floor. This of course made a racket that got everyone’s attention. I then picked up the VCR, looked it over, shrugged, dropped it in the nearest garbage bin, and walked back to my office.

This then caused an explosion of concern on the part of my staff. Everyone came running over, someone fished the VCR out of the trash … was everything all right? What happened?! Did I want them to test the VCR to see if it was still OK, etc. I then told them that they’d been punked and we all had a good laugh and got back to work. That said, I was touched by the outpouring of concern.

Old Sayings, New Sayings

We had a dry erase board out on the wall outside my office where we would list the various jobs being built. This was above a row of six bins that held the paperwork, labeled (IIRC): To be built, in progress, out-of-shop, back in shop, to be checked in, and completed.

I’d gotten tired of drivers from other companies having a nice long look at our job board while they were waiting to pick-up or drop off a cross rental so around 1995, we switched to a system wherein each show was built (and labeled) with just the job number and the account manager’s initials. Going from “The Fabulous Whatever Band – Maple Leaf Gardens” to “IZ-5634” for every show left a lot of extra room on the board for other content, so I would occasionally put some saying up there. I only remember two of them.

The first was a riff on the Nike “Bo Knows” ad campaign of the early 90s that read: “Bo knows the mayor of Palm Springs, CA (Sonny Bono, at the time), Bo knows the lead singer of U2 … Bo knows Bonos!” And the other, which I attributed to Albert Einstein was: “Zero KiloHertz is 0K by me!”

And finally, I can’t recall if I actually did this, or I just really wanted to, but … we had so many problems with truck packs early on in my tenure that I insisted on inspecting every load before it left the shop. (Cube vans so overloaded that the box was resting on the rear tires was a particular favorite.) In any case, when confronted with a truck pack that wasn’t up to my standards, my inclination was to belt out the first line of the song, “He Ain’t Heavy, He’s My Brother” only with the second part of the lyric rearranged to, “The LOAD is Wrong…”

Eventually, the outbound truck packs improved to the point where I didn’t need to inspect them anymore, but I would occasionally be called to the loading dock to look over a particularly disastrous returning load. I can only remember one of these.

The truck was a complete jumbled mess with gear toppled all over the place. When I called the tech and demanded to know what had happened, he patiently explained to me that he had been booked on some kind of private rock show, in the middle of an open field somewhere (I believe the clients were … um … “motorcycle enthusiasts”) and that all of the “help” had bailed after the show, leaving him alone, in the dark, to load the truck.

That he had accomplished this at all was a minor miracle, especially when he told me that the only way he could get our 375-pound, twin 12-inch monitor cases (with two per case) up the ramp was to use a couple of heavy ratchet straps as “come-alongs” to winch them up the ramp. It didn’t take too much imagination to realize how badly that could have ended up, so I redirected my attentions to the account manager for putting an employee in that situation in the first place.

A story that I don’t remember did leave a lasting impression on the recipient who I still work with a few times a year. He maintains that the strip that I tore off him for bringing back a truck with a bad load was the first step on his path to sobriety, which he has maintained to this day. As I said, I don’t recall the incident, but he reminds me of it and thanks me for doing it every time I see him, and I’ll take that.