It used to be that the fragile nature of ribbon microphones made them unsuitable for most live sound applications. But not any more – many recent models have been beefed up for added ruggedness, which is great because it allows us add their special sonic qualities to our live mixes.

Let’s explore the unique devices that are ribbon mics, including their design, technology, application, and techniques of use.

Physical Design

The majority of dynamic mics are based on moving coil designs, but ribbon mics are also a type of dynamic. They both convert sound into electricity using a magnet and a moving conductor.

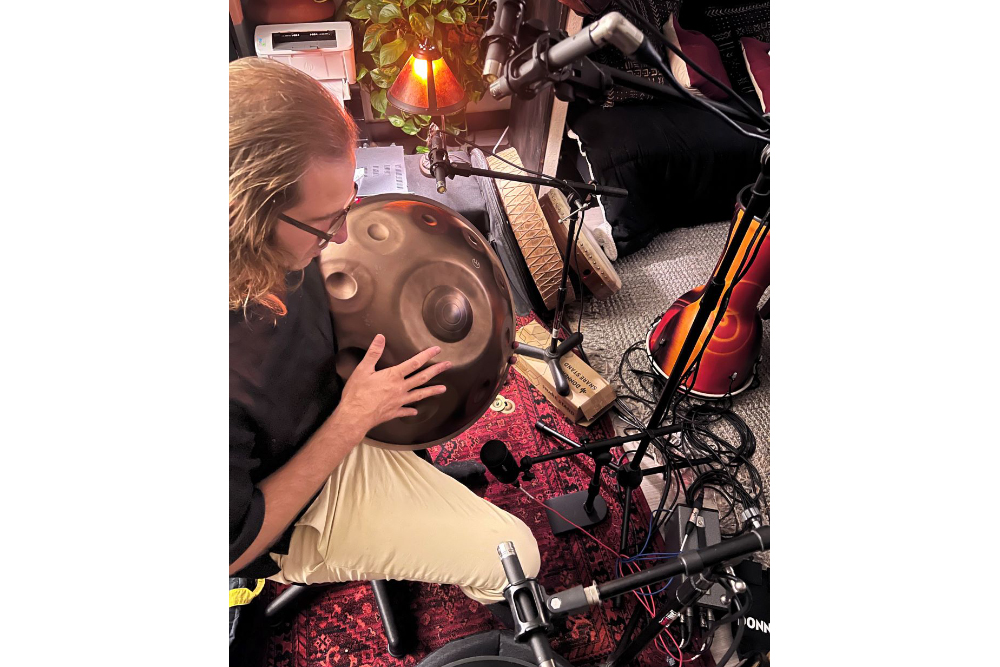

In a ribbon mic capsule, a thin strip of aluminum foil (the ribbon) is suspended in a magnetic field (Figure 1). Sound waves vibrate the ribbon in the field and generate an electrical signal. The magnetic lines of force are cut by the ribbon as it moves, so a voltage is induced across the ribbon proportional to the velocity of the ribbon. So the ribbon is both the diaphragm and the transducer.

Typical ribbon dimensions are 1 to 2.4 inches long, 0.2 inch wide, and 0.6 to 2.5 microns thick. (A micron is 1/1000 of a millimeter!) Because the ribbon is so small and thin, it has an extremely low mass, which gives it a very fast transient response – producing a detailed yet warm sound.

The ribbon is corrugated like an accordion to reduce resonances and to prevent curling at the edges. If the corrugations are few and shallow, the ribbon tends to fatigue easily.

Active models further boost output level by using a built-in, phantom powered mic preamp. The preamp also isolates the ribbon from loading and from miswired phantom power. The typical self-noise of a ribbon mic is less than 17 dB (A-weighted).Being a short conductor, the ribbon has a very low impedance. A step-up transformer inside the mic raises its output impedance – and its signal level – to usable values. Older designs tended to have very low sensitivity because of the weak fields of their alnico magnets. Modern designs use neodymium magnets with higher flux, which, in turn, provides higher output.

Response

Ribbon mics tend to have a flat frequency response and a high-end rolloff because the ribbon is stretched very loosely so that it has a low resonance frequency, around 30 Hz or higher.

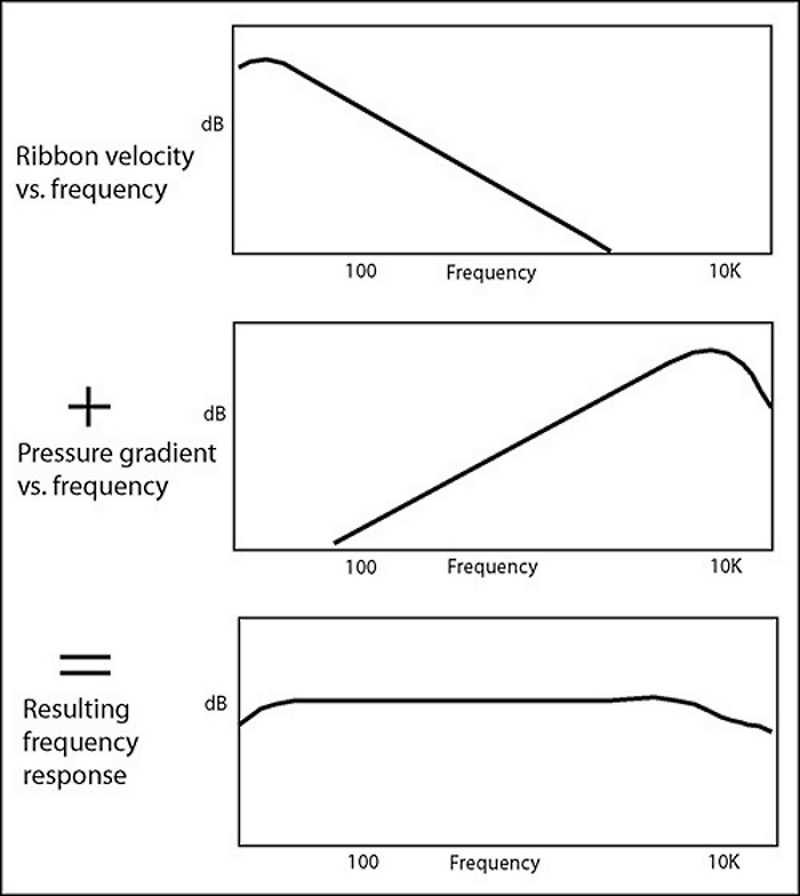

The resonance is damped by resistive fabric or screen near the ribbon, and by the resistance of the air gap between the ribbon and magnetic pole pieces. It’s also damped by the mic preamp’s input impedance. Above resonance, the velocity of the ribbon vibration drops 6 dB per octave.

The ribbon is open to sound waves on front and back. It responds to the pressure gradient (difference in sound pressure) between the front and rear of the diaphragm. At low frequencies with long wavelengths, the pressure gradient is very low.

At high frequencies with short wavelengths, the pressure gradient is high. The pressure gradient rises 6 dB per octave, then falls off at very high frequencies (small wavelengths) because both sides of the ribbon are exposed to successive sound-wave compressions.

Add those two effects together, and you get the net frequency response of the ribbon mic. It tends to be flat above resonance, then rolls off at higher frequencies, giving a smooth, mellow high end. At high frequencies, sound-pressure buildup on the ribbon and pole pieces helps to lift the highs. Then there’s the mic grille, which introduces small peaks and dips in the overall response, just as in any other microphone design.Figure 2 shows how the frequency response of a ribbon mic is produced. The ribbon’s velocity versus frequency falls 6 dB per octave above its resonant frequency. The pressure gradient across the ribbon rises 6 dB per octave.

Both moving coil and condenser designs have a resonant air chamber in front of the diaphragm. This Helmholtz resonator (air resonance in a cavity) boosts upper frequencies to create a more extended high-frequency response.

However, ribbon designs omit the resonator, so there is less ringing and phase shift in its signal at high frequencies – a “rounded off ” sound that is easy on the ears. Some mix engineers say the sound is particularly complementary to digital recording.