Too many good folks have been separated from their hard earned money by hyperbolic claims about loudspeaker wire. There will always be people with more dollars than sense, but they don’t last very long in professional audio.

I speculate there aren’t many (if any) of you who would pay thousands, or even tens of dollars per foot for speaker wire.

A very basic practice in merchandising is called differentiation. Marketers must come up with reasons for why you should buy their wire. To claim that their wire is better, they must first identify, in some cases invent, a difference.

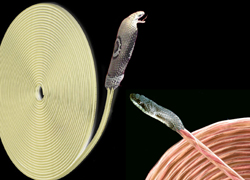

This search for a selling proposition has sometimes focused on “skin effect.” It’s a real effect and describes how at very high frequencies, electrons travel in the outer layer or “skin” of signal conductors.

Another related property is that high frequency signals travel faster than low frequencies through the same cable.

These phenomena are dealt with appropriately in very high frequency applications with several techniques. “Litz” wire is made up of a large number of very small conductors braided or woven into one cable, producing a large surface area or “skin” for a given cross sectional area.

Another approach for high power high frequency power transfer is to use a hollow conductor, resembling a section of copper tubing. If the electrons are going to ignore the center of the conductor, why pay for it?

This is not an issue for audio professionals, working at mere audio frequencies of 20 Hz to 20 kHz. Perhaps it would be if we were sending audio over many miles, like the telephone company in its pre-digital days. They had to periodically correct for waveform smear. But at the speed that electricity travels, our typical path distances are much too short to be an issue.

OUT OF PERSPECTIVE

Wire is not very sexy or easy to create real marketing hooks for, but it can actually make an audible difference. The dominant mechanism is simple resistance. It’s perhaps ironic that the “snake oil” markers of speaker wire will exaggerate some real but insignificant parameter far out of perspective while compromising the real deal.

Forget the hype, what’s important for speaker wire is that it exhibit low impedance that is resistive in nature. If the wire has a significant impedance component (reactance) that changes over the audio frequency spectrum, this can form a simple divider with the loudspeaker’s resistive impedance and cause a frequency response error.

In addition, since loudspeaker impedance will vary quite a bit over frequency, even a perfectly resistive speaker wire will cause errors. The magnitude of this frequency response error will increase proportionately as the wire’s resistance increases.

Purveyors of “funny wire” don’t bother to make claims about useful metrics like resistance since that is already defined by the wire size or gauge (known as “American Wire Gauge” or AWG for short). That would be like advertising how many quarts were in their gallons!

However, frequency response errors caused by wire resistance are one of the very real things that people actually do hear.

I find this following anecdote instructive. From a discussion with one individual who was certain that he heard a significant improvement when using his “Snake-O Special” speaker wire (name changed because I don’t remember it), I determined that the wire gauge he was using was marginal for the length of his run. The wideband loss of volume caused by a wire’s resistance will be very difficult to hear without a side-by-side comparison.

But the difference in amount of loss caused by the speaker’s changing impedance at different frequencies can easily cause a frequency response error that is probably what he heard. It’s easy to imagine how a rising impedance at high frequency could cause a pleasant sounding treble boost. Just listen to how clean and clear these “Snake-O Specials” sound!

There are several strategies to manage these real losses from wire resistance. The obvious one is to throw more copper at the problem. Heavier gauge wire with lower resistance will exhibit lower losses for a given run length. Another fairly obvious approach is to locate the amplifiers as close as possible to the loudspeakers to keep the run length as short as possible. A third less obvious approach is to scale up the intermediate signal voltages.