The entire industry knows (or should) that loudspeaker drivers are fragile, and that careful attention needs to be paid to how much amplifier power is applied to each component in a sound system.

This is especially true in our world of live sound, where we are always trying to push our loudspeakers to get those last few decibels or final quarter octave of performance. While the technology behind transducers has advanced considerably in the last few decades, providing significantly higher power handling and wider bandwidth, it is just as important to know how to properly power a loudspeaker today as it was at the dawn of sound reinforcement.

If you spend much time on Internet resources like the Live Audio Board, you will probably have been exposed to a veritable color palette of plausible reasons for driver failure.

I have seen visitors advised that their drivers failed because of amplifier clipping, over-powering, under-powering, improper limiter settings, DC, square waves, over-excursion, choice of crossover point, system compressors, no system compressors, music genre, improper horn loading, heat, cold, and humidity. I’m probably skipping a few, and you’ve probably heard most of these complications yourself.

This wide variety of often incongruous explanations makes it difficult for even many advanced users to decide on the simple matter of how much amplifier power to provide a given loudspeaker component.

Failing Loudspeakers

Fortunately, the real answer is quite simple, and takes into account all of the aforementioned explanations. Loudspeakers fail for two reasons, over-heating and over-excursion.

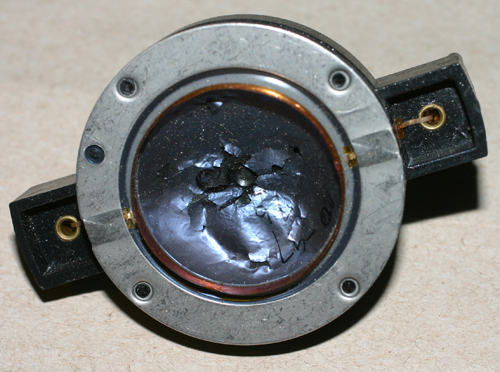

The former burns up the voice coil, freezing it in the magnetic gap or causing the circuit to open. The latter tears the loudspeaker apart as it is slammed back and forth against its mechanical limits by its own reciprocating motion. While it is certainly not uncommon to see drivers fail due to being kicked, dropped, or soaked, failure due to physical abuse not provided by an amplifier is academic to the purpose of this article.

Over-excursion is a well-understood phenomenon. It is simple to observe, can be measured with a ruler, and reasonably accurate formulas exist to calculate it based on the enclosure the driver is loaded into and the frequencies being amplified. Failure is simple to document, as the driver will look like it was torn apart by force, with obvious consequences to the cone, surround, and voice coil.

Some loudspeakers deal with over-excursion better than others, but it is never a good thing. Component manufacturers will list the maximum limits of their drivers’ mechanical suspension as the XMech specification, which is almost always more than the XMax spec; the latter refers to the point at which the voice coil has achieved enough excursion that part of it has left the magnetic gap. (See Exhibits 1 & 2.)

The driver has started to lose control of the cone at this point and distortion rises rapidly. It is a good idea to avoid taking a loudspeaker past XMax as there can be severe consequences to sound quality, although the driver will probably survive.

Too much time spent at or near XMech will almost certainly destroy the driver. A good engineer will probably be able to hear when they approach XMax and back off, realizing that’s all the “rig for the gig” they have.

Even a bad engineer can probably hear XMech as the voice coil bottoming out makes a lot of noise, and if they don’t notice that, the loudspeaker blowing apart shortly thereafter is a sure indicator. Overheating, on the other hand, is not very well understood or simple to measure and document.

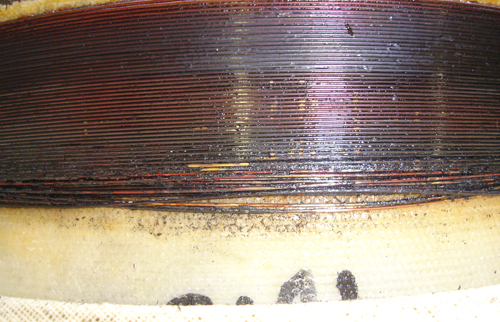

Think of the loudspeaker’s voice coil as if it were a space heater: apply a certain amount of voltage, and the coil heats up. Very little voltage produces very little heat. A lot of voltage will produce a lot of heat, until the voice coil is producing more heat than it can handle and burns up.

Unlike a room heater’s glowing red element, a loudspeaker voice coil is made up of very fine and fragile wire.

To help it survive the kind of power we expect in pro audio, the voice coil is cooled both by sinking heat into the magnet assembly it rides in, as well as by pumping cool air around the magnet structure through the motion of the cone.

Modern voice coils can handle a great deal of heat, but there are still very definite limits. (See Exhibit 3.)

Crest Factor

What complicates the amount of heat a driver can take is something called “crest factor.” The crest factor of a waveform is the ratio of its peak amplitude to its RMS value, which can be expressed in dB.

A pure DC signal has 0 dB crest factor. A pure sine wave has 3 dB crest factor. Pink noise has a crest factor of 6 dB. Any two signals that have identical RMS values will create the same amount of heat, but the one with the higher crest factor will have higher peak amplitude, which can make a large difference in the way it sounds.

Most importantly, live music commonly has a crest factor around 20 dB, 100 times more peak power than RMS!

This crest factor is the reason that loudspeakers and components are often given three power ratings, usually described as continuous, program, and peak. In reality, these are just different ways of saying the same thing, but with varying crest factors.

Continuous power is defined by the AES standard IEC 268-5 as the amount of power a loudspeaker can handle over a long time period (hours) when driven with pink noise (6 dB crest factor) that is limited to the driver’s operating bandwidth.

This is a pretty good “worst case” scenario, as any music that you are trying to reproduce that has only 6 dB of peak to average ratio is going to sound like noise anyway. A program rating for the same loudspeaker is then usually listed, and it is 3 dB higher, or twice the wattage.

At least one major manufacturer doesn’t even list the continuous (AES) power rating for their loudspeakers, because the number that is twice as large looks twice as good to the consumer. They list program and then peak, which is 3 dB more than program and twice the wattage again.

What is important is to realize that all these numbers are simply made up, and the higher numbers simply represent the amount of amplifier power one should apply when reproducing signals with more dynamics, headroom, crest factor, or whatever you’d like to call it.

These numbers assume that the average power of the signal will be the same at each power rating, but as each signal has a progressively higher gap between its peaks and its RMS value, more peak amplifier power output can be applied to reproduce those peaks without overheating the driver.