In EASERA, there is not an ohm display selection. Selecting a volt display will yield the correct values for the displayed curve.

For other measurement systems this may work as well, but it is recommended to check the display by measuring a known resistor value for proper calibration.

A very useful device for performing impedance measurements using this current sensing resistor method is the VI Box from LinearX.

The signal from the amplifier is routed through the VI Box, which contains the current sensing resistor, and then onto the DUT.

It actually contains two selectable sensing resistors, 1 ohm and 10 mohm (milliohm), which allow for measurements using a greater range of current supplied to the load (DUT).

The voltage across the selected resistor is present across pins 2 and 3 of one of the XL connectors.

The voltage across the DUT is present across pins 2 and 3 of the other XL connector. These connectors allow for quick and easy interface with balanced inputs of a computer/audio interface (sound card).

There is also a selectable voltage divider so the input of the audio interface won’t be overloaded when testing with very high voltage.

I mentioned earlier that measuring input impedance at low drive levels may present a problem for some applications. A couple of these that come to mind are vented loudspeaker enclosures and constant voltage distributed system transformers. I’m sure the interested reader will find others.

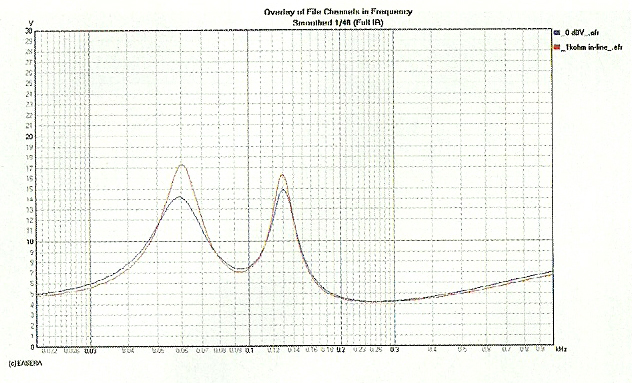

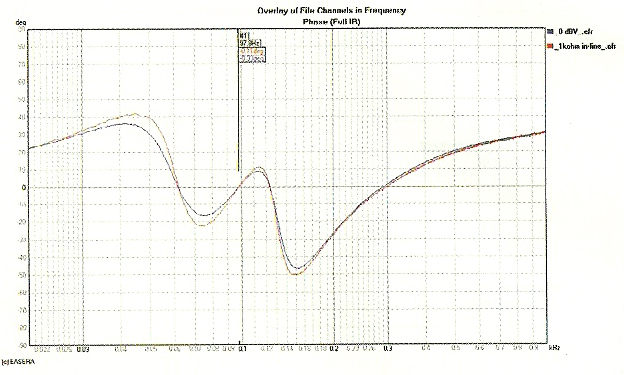

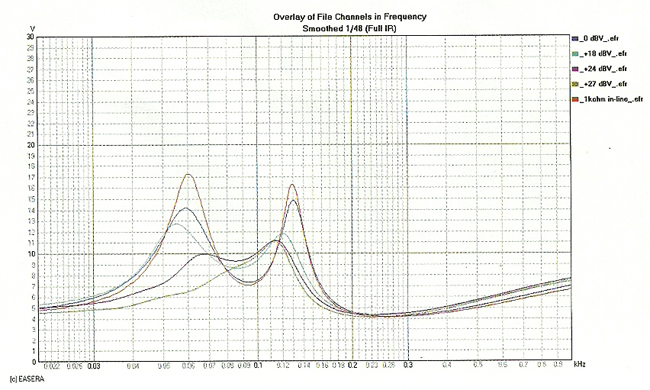

The impedance response of a vented loudspeaker enclosure is shown in Figure 3. The angle of the impedance for this device is shown in Figure 4. The vent tuning resonance of this

loudspeaker is found when the impedance angle is zero indicating the voltage and current are in phase. This is denoted by the marker at approximate 98 Hz.

These graphs show measurements using both the constant current method with a 1 Kohm resistor and using a current sensing resistor. The current sensing resistor measurement used a 0 dBV (1.0 V) drive level to excite the loudspeaker.

There is some difference between these two measurements. The impedance measurements in Figure 5 tell us much more. In this graph we have additional measurements at +18, + 24 and +27 dBV. We can see that at these higher drive levels the impedance curve changes rather dramatically.

The vent surface area of this loudspeaker is relatively small compared to the surface area of the driver. When the woofer is driven harder it moves a lot more air. The vents are too small to allow this same volume of air to be moved through them. The vents saturate.

As more air attempts to move through the vents, they saturate more and have less of an effect on the loudspeaker response. The impedance response begins to look less like a vented box and more like that of a sealed box.

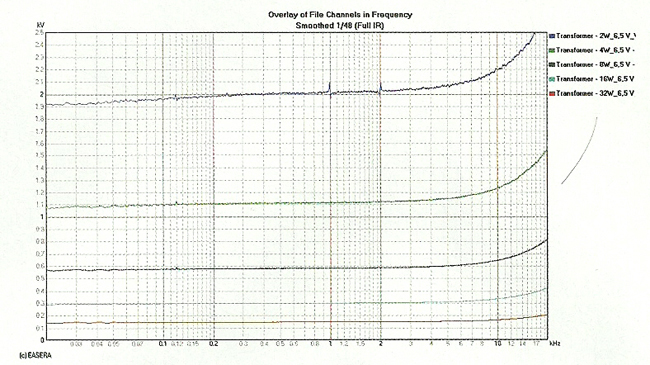

A constant voltage distributed loudspeaker system typically requires transformers to be placed immediately in front of the loudspeakers to step down the voltage and step up the current. Testing these types of transformers at low voltage levels typically will not reveal some of the problems that may occur in actual usage.

Figure 6 shows the input impedance for each primary tap of a 70.7 V step down transformer with its secondary loaded by an 8-ohm power dissipation test resistor. For each of these measurements the drive voltage was 6.5 V. This is approximately -21 dB from the full rated voltage of 70.7 V.

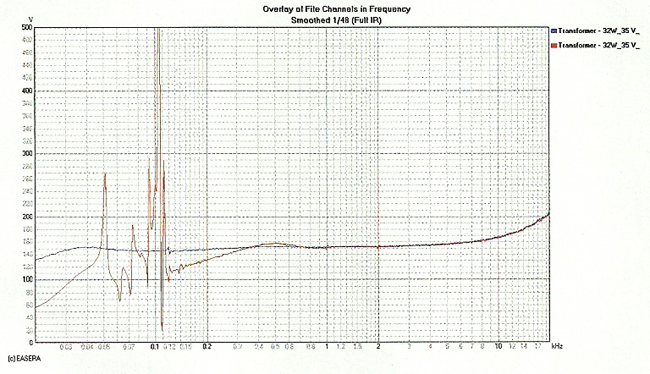

As expected the impedance curves are fairly well behaved. When driven at 35 V, -6 dB from full rated voltage, there is a problem with the 32 W tap seen in Figure 7. At very low frequencies this transformer does not like being driven at this voltage. The result is that the core saturates. The reflected impedance of the load (on the secondary) as seen by the primary is no longer linear.

This violates one of the requirements of the measurement method used (FFT); that the DUT be linear, time invariant (L11). By placing a second-order Butterworth high-pass filter in front of the amplifier driving the transformer this core saturation condition can be corrected. A doubling of voltage to 70 V would require the corner frequency of the high pass filter to also be doubled. In this case, the corner frequency should be increased from 30 Hz to 60 Hz.

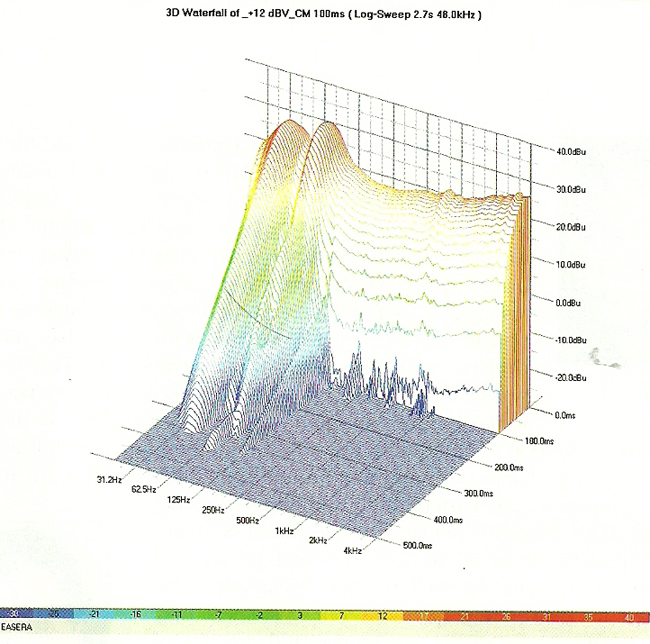

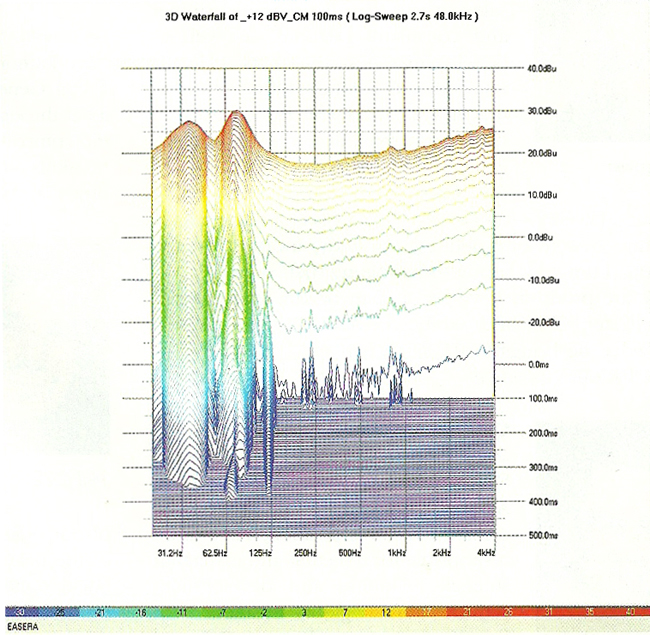

Another use for these types of measurements is to investigate resonance behavior. This can be particularly interesting when viewed as a 3D waterfall. The impedance response of a vented enclosure is shown in Figure 8. There are two features in this graph that should be noted. This is the dip/peak at 80 and 120 Hz.

Notice these same frequency regions in Figure 9 and Figure 10. These features don’t occur initially. It is only after approximately 60 ms that they become evident. Knowing how long it requires for this resonance to develop may help in determining its cause and implementing a solution.

I hope that the method discussed here to measure impedance at typical application drive level and illustrating some possible uses will be of benefit. Thanks to Jay Mitchell (Frazier Loudspeakers) and Dr. Eugene Patronis (Professor Emeritus, Physics – Georgia Institute of Technology) for their insights on some of these applications.

Charlie Hughes has been int he pro audio industry for over 20 years, having worked at Peavey and Altec Lansing. He currently heads up Excelsior Audio Design & Services, a consultation, design and measurement services company located near Charlotte, NC. He is also a member of the AES, ASA, CEA and NSCA, in addition to being an active member of several AES and CEA standards committees.