At Electro-Voice, sound quality is paramount. It’s been that way across the company’s illustrious 90-year history, and has never been more so than today. The backbone of the effort is a world-class research and development team, which works in state-of-the-art facilities stocked with leading-edge tools at company headquarters in Burnsville, MN, just outside of Minneapolis.

“It all starts with the people, and what we seek from every member of our team is the right combination of solid, foundational engineering skills blended with creativity and passion,” explains director of engineering Bill Gelow, who’s led the department for more than 17 years following key roles with several top professional audio manufacturers.

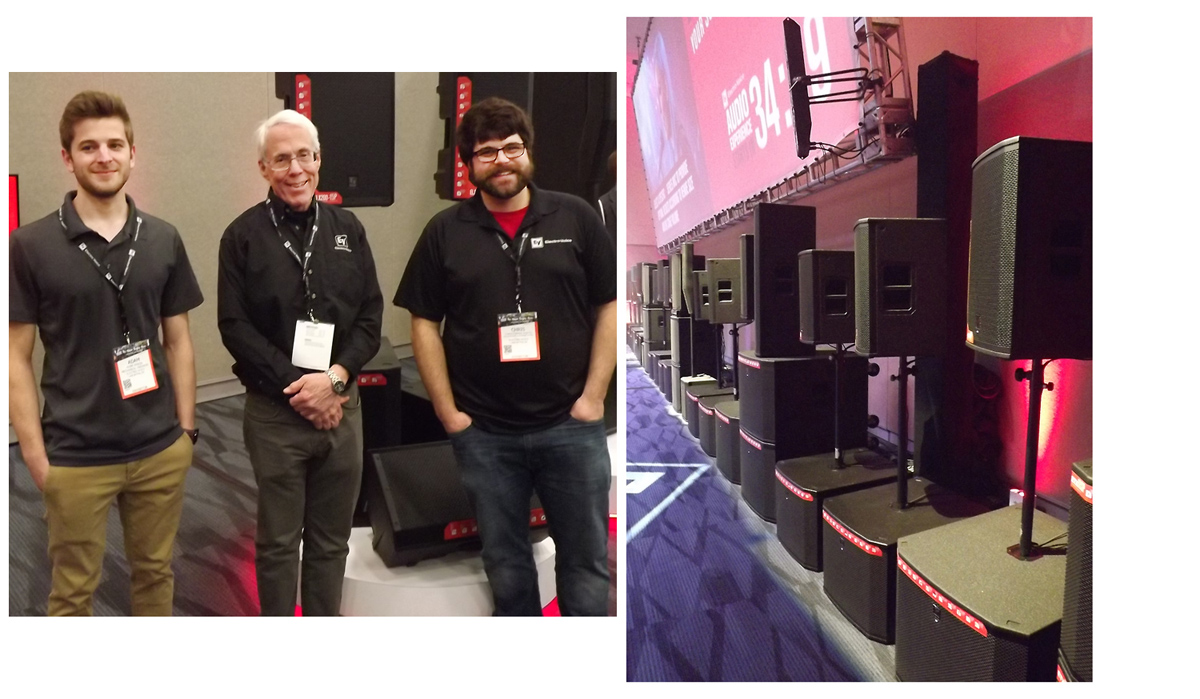

The bedrock of the EV approach to product advancement is exuded by chief engineer Dave Carlson, who’s played an enormous role in the development of numerous game-changing (and patented) loudspeaker technologies over more than three decades with the company, working with great group of younger talent such as principal engineer Mike Kasten, who came aboard immediately after earning a degree at Michigan Tech.

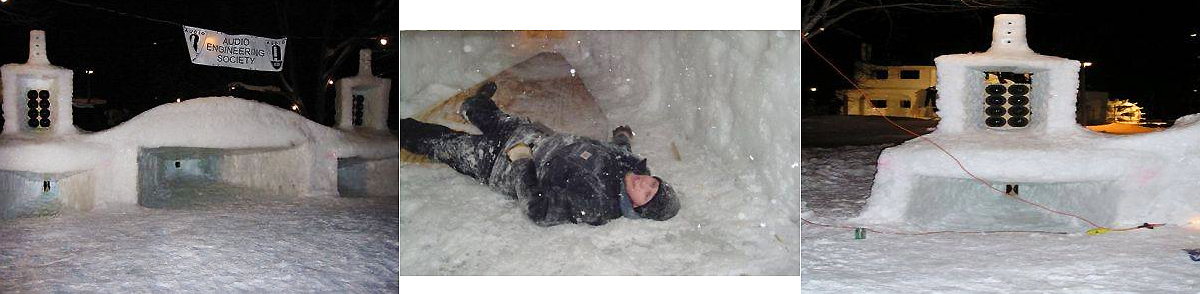

“There’s a wealth of engineering talent in the younger generation, and that’s exemplified by Mike,” Gelow notes. “We learned of him via his involvement in an outstanding AES (Audio Engineering Society) chapter at Michigan Tech, and in fact, we’ve also brought onboard two more engineers from that deep talent pool, including a PhD mathematician who’s a speaker guy. It’s been a driving catalyst that spurs our development efforts to further heights. These are very knowledgeable individuals, of course, but the real difference-maker is that they also have a true passion for audio, technology and engineering.”

Kasten hit the ground running upon joining the department in 2006, focusing first on refining the digital signal processing (DSP) that works in tandem with many of the company’s loudspeakers, as well as refining data and measurement processes. “The goal was taking what we’d been doing, which was already quite good, and improving upon it with new and alternative approaches; in other words, taking things to the next level.”

He’s since transitioned to loudspeaker system design, including participating in the transducer development that’s key to the success of those systems. Over time the role has expanded to all facets of loudspeaker systems: “Everything from cabinets to rubber feet and everything in between,” he notes with a laugh.

Carlson, meanwhile, serves as the “glue” of the loudspeaker development program. Since joining the team in 1985, he’s contributed to countless systems, including Manifold Technology, X-Array and X-Line concert systems, and has mentored many new pro audio engineers along the way in step with these developments in system design.

Carlson too possesses the multi-discipline skill-set that’s a hallmark of the EV engineering team, beginning with a primary focus on large-scale sound reinforcement systems that continues to this day, along with transitioning to also working with transducers and horn design. “It’s a little bit of everything, contributing what I’ve learned as well as fostering the work of others,” he explains.

This is a main theme throughout the EV engineering group: a diverse set of engineers working side by side, sharing what they know with each other. With new engineers working alongside seasoned veterans on all EV engineering projects, it’s a rich learning environment, and sometimes it’s the veterans who learn from the younger team members.

While he’s already quite busy directing and staffing a dynamic, growing R&D effort, Gelow manages to stay engaged in hands-on activities as well. “I remain fascinated by compression drivers and waveguides, so that’s where I put my focus every chance I get,” he says. “There’s just something about generating tremendous high-frequency energy and then being able to focus and control it that really intrigues me as an engineer.”

He also points to the X-Line Advance X2 line array as a particular recent highlight and one that exemplifies the EV approach: “It’s a project that morphed over time into something that Dave, I, the transducers folks, and a couple of others really wanted to do, and then a whole lot of our team contributed valuable work in making it happen. It was a collaboration of dynamic talents, and the end result of that teamwork is something we’re all quite proud of.”