We made things user friendly in terms of device naming; 192.168.1.101 was house left, 192.168.1.102 was house right. Later when we deployed more (which isn’t part of this saga,) we followed the same convention and went around the stage from upstage HL to upstage HR, .101 to .106. The manufacturer will also supply an Application Program Interface (API) if there are multiple units on a tour and want to see all units at the same time on your device.

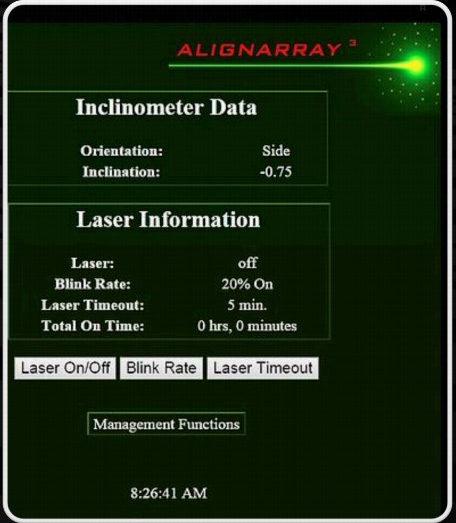

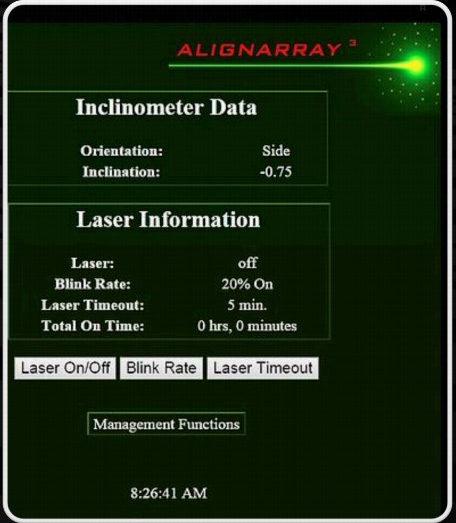

The beauty of the networked inclinometer has two benefits: time and trust. With my browser enabled and phone in hand, I now don’t need to get a PA tech back to position to toggle a laser or confirm an angle after the cluster has settled (or if I’m just being OCD). That saves time.

I also can see for myself whether someone is rounding up or down or to what they feel is “close enough.” I’m the one who gets to determine if .5 degrees over 400 feet is kind of a big deal.

The network we used had lots of other traffic on it and was definitely being stretched as far as bandwidth, but the Alignarray connections didn’t seem to have any effect on our other packets flying to and fro. In addition to the nifty blinking feature and the ability to change that blink rate on the inclinometers is very useful. (Change it to, say, the BPM of “Stayin’ Alive” in case you need to do CPR and angle the PA simultaneously.)

The devices also have a time-out feature for when you forget to shut them off. This can be disconcerting for the paying audience if they show up to find a very bright laser dot targeting their heads.

Minor Notes

So… what can be done better? A couple of things.

The UVM Clamp mount universal adaptor has a very well machined knurled knob that uses a set screw to fix the knob to the shaft. It loosens quickly and no one I know carries Allen keys on their Gerber. We modified the mount with some lite sheet rubber to give it a better fit and to reduce marring the bumper finish (or loudspeaker handle).

There are some orientations of fitting the Alignarray to both its universal mount options (UVM Clamp mount and UVM Bumper mount), which do not give you a position for running a safety thru the combined unit. I’d also feel better if I could connect a safety directly onto the device itself. Perhaps a threaded and nylon nutted shoulder bolt might be a good option.

As you can see, most of those criticisms are mechanical and revolve around the universal mount. In their defense, universal mounts for anything are, by definition, a compromise. There are specific mounts made just for individual loudspeakers from manufacturers such as L-Acoustics, d&b audiotechnik, Meyer Sound, VUE Audiotechnik and JBL, among others.

At the end of the day, we solved the safety mount issue easily by drilling a small hole into the mount itself and running a safety thru it. Problem solved.

The more important part of the experiment actually came at the end of the run a few weeks later. After being bumped and tussled in trucks for many miles, the units themselves never lost their calibration, nor did their lasers deflect off of zero. That doesn’t seem like a big deal, but keep in mind how much you count on your up or down sight angle being exactly what you designed with your prediction.

Also, think about how much force of will it takes to not turn a laser on and bump the array until the dot lands where you want it. What if you were bumping away, only to find out your laser deflection from zero was off… even slightly? Over the long distances we’re covering with today’s very vertically directive loudspeaker arrays – being off, even slightly, is the difference between “great job!” and “we had to refund the back rows.”

Personally, I prefer tools that keep comments like the first one coming.