Some in audio think that the term “rigging” only applies when loudspeakers are flown, but it also pertains to lesser endeavors such as placing a single loudspeaker on a tripod stand. The bottom line is that for any piece of production gear not sitting directly on the ground, steps must be in place to insure that it does not fall and injure someone (or worse).

The Occupational Safety and Health Administration (OSHA), the U.S. agency that sets and enforces work safety standards, states a company must have “competent” and “qualified” persons in charge of rigging. A competent person is described as one who is capable of identifying existing and predictable hazards in the surroundings, which are dangerous to employees and has authority to take prompt corrective measures to eliminate them.

Meanwhile, a qualified person is defined as one who by possession of a recognized degree, certificate or by extensive knowledge, training and experience, has successfully demonstrated the ability to solve problems relating to the subject matter and the project. Therefore, a qualified person designs a rigging system, and a competent person installs and monitors the rig, and inspects its components.

While OSHA rules and standards are mainly focused toward rigging in the construction industry and are geared toward safety of employees, we also need to look after the safety of performers and members of the public who attend events. Not everyone at a gig may be at the level of a qualified or competent person, but all should focused on safety. Anyone on a production crew who sees a problem with rigging (or any other safety issue, for that matter) can call “stop” and point out the issue so it can be addressed and corrected to avoid an accident or injury.

Good places to look for training and information are manufacturers who make rigging equipment or loudspeakers that fly. They provide specific safety and operating instructions for their own gear. Two organizations focused on entertainment rigging training are the ESTA Foundation and PLASA, which offers the ETCP rigging certification program for entertainment riggers who work in theaters or arenas.

There are also several independent rigging schools and manufacturers that offer training and certification programs as well. A good reference book is Entertainment Rigging by Harry Donovan. While reading about proper rigging practices is highly recommended, it’s not the same as getting hands-on training. Experience along with knowledge is required for a person to be designated as competent.

The Essentials

Before we talking about specific rigging approaches, let’s look at a few terms. Initials often seen on stands and rigging equipment are “WLL” (Working Load Limit), “SWL” (Safe Working Load), or “MRL” (Maximum Rated Load).

For practical purposes, they mean basically the same thing: the maximum amount of static weight that the item will safely hold continuously, when it is used correctly as intended. The key here is a static load, or a load that does not move. Any movement like loudspeakers swinging in the wind or even the act of raising or lowering a chain motor puts additional stresses on rigging equipment. Safe working load limits should never be exceeded.

Another term to be familiar with is “Safety Factor,” the margin of safety added to an item that takes into account loadings over and above the weight being hoisted and for reductions in capacity due to the extra loads imposed by acceleration and inertia (movement).

Some European countries have mandated 10:1 safety margins, while those in the U.S. are still largely self-enforced. Many production companies in the U.S. have adopted a 7:1 safety factor, with margins for life safety (fall arrest, performer aerial acts, etc.) using a 10:1 ratio.

In short, an item’s safe working load is derived by dividing the breaking strength (the point of failure) by the safety factor. An example would be a shackle with a breaking strength of 7 tons would have a safe working load of 1 ton here in the U.S. (SWL= Breaking Strength (7 tons)/safety factor (7:1).

System design plays a large part in the rating of individual components. Like a chain, a rigging system is only as strong as its weakest link. Pull angles and side loadings de-rate the SWL of many items including eye bolts and shackles.

The splay angle of bridles (two or more legs of wire attached to a ring that spreads the load across a larger area) affects their weight loading. Spansets and wire rope slings will have different capacities based on their positioning (i.e., straight vertical pull versus a basket configuration).

All of these factors need to be taken into account by a qualified person who will design the rigging system.

In addition, a competent person should inspect all rigging equipment and hardware before use and periodically do a major inspection for signs of wear, abuse and general adequacy, as well as perform any manufacturer recommended preventive maintenance.

Follow the rules and don’t cut corners when it comes to rigging. Use only loudspeaker cabinets designed by the manufacturer to fly, and use only hardware approved for that specific model. Follow all manufacturer recommendations concerning their individual products. Never modify any rigging hardware as it may affect the weight loading capacity of the item. Purchase only known quality rigging equipment.

Further, factor in enough time to do rigging correctly and make sure the crew isn’t tired—rushing and fatigue cause accidents. Double check everything before it goes up in the air. Once items leave the ground, they better be rigged properly or gravity will demonstrate why it’s the most powerful force in the universe!

Only finger tighten shackle bolts, never use a tool. If you’re worried that a pin might vibrate out, mouse (secure) the pin in place with twine or wire. Always load a shackle pin to end, never from side to side. When attaching to a beam or other structural component, always pad the beam edges so a sharp edge doesn’t injure the wire rope or sling. Never leave any slack in guy wires.

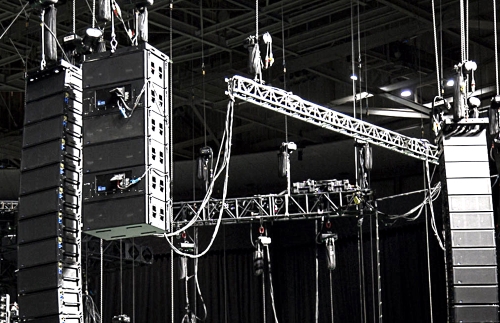

Plenty Of Methods

Now let’s move on to looking at ways loudspeakers can be deployed and positioned.

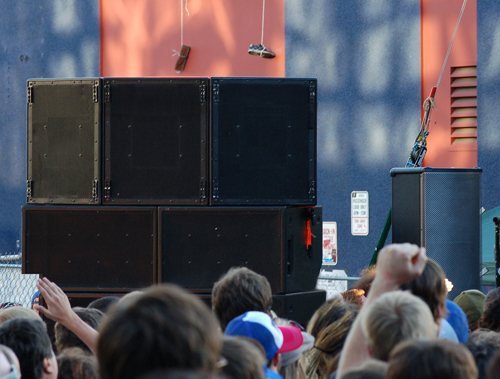

Ground Stack. The easiest way to set up a PA is by placing it on the ground or stage. While this method seems to have no dangers associated with it, there are a few lurking. Loudspeakers stacked on top on each other can fall from the stack due to vibrations. Truck straps are commonly employed to keep them from vibrating apart.

Keep in mind, however, that strapped stacks can be top heavy and can topple over, either from vibrations or from a crowd pushing to get closer to the stage. Using a larger subwoofer that provides a bigger footprint as the base of a stack can add stability to a strapped stack of loudspeakers.

Many line arrays are designed to be ground stacked by inverting the fly bar and using it as a base. The cabinets are connected to each other and the base with their fly hardware, making a stable ground stack with the angles being able to be adjusted for coverage same as when flown. Loudspeakers placed on uneven terrain will be unstable and if used on a grass or dirt surface could shift during rain. A common remedy is to place a stage or plywood platform on the ground and level it. Then the loudspeaker stack will have a solid level surface to rest upon and not sink into mud after a rain storm.

Scaffolding. Before flying PA was common practice, stacking loudspeaker boxes on scaffolding towers was a common approach at larger shows. It’s still a common way of elevating horizontal arrays and delay stacks at festivals and fairs. On uneven ground, screw jack leveling legs should be used to ensure the scaffolding is level and all cross and diagonal bracing needs to be in place before loading the tower. Make sure all decking is securely in place before any speakers placed on the tower and they should be strapped down so they can’t vibrate off.

If used outdoors, the tower needs to be guyed down in case of winds. Signage and banners placed on the scaffolding act like sails and will transmit high wind loading to the system. Using an open weave fabric for the signage will allow some wind the blow through, reducing the wind loading on the tower.

Banners should have a quick release system in place so they can be removed rapidly in case of unexpected high winds. Line arrays can be flown inside scaffolding towers, with the chain motor for the array usually connected to a beam secured across the top of the tower.

Make sure the beam is secured to the tower and not just held in place by the weight of the PA.