How is low-capacitance cable made?

Given that the overall outside diameter of the cable is limited by the plugs that must be used, cable capacitance is largely the result of trade-offs between conductor size (and hence strength), insulation material (cost) and insulation thickness (size and flexibility).

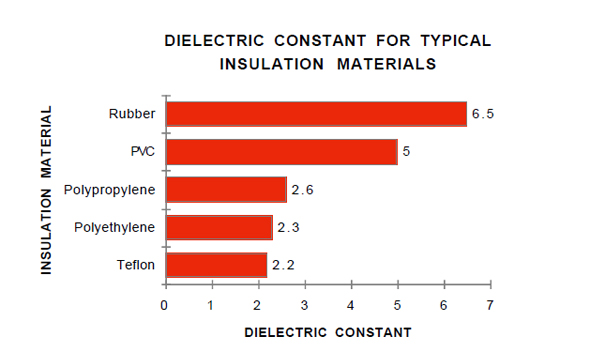

The term dielectric constant is used to rank the insulation quality of a material.

Some materials are great insulators but impractical for use as wire insulation—glass, for instance! As far as practical materials are concerned, the thermoplastics are generally far superior to the thermoset family.

For instance, polyethylene has a dielectric constant of 2.3, while that of rubber is 6.5. This allows a cable with polyethylene insulation to have perhaps one-third of the capacitance of a cable insulated with the same thickness of rubber. It can make an audible increase in the clarity of the sound.

What is the best all-around insulation material for instrument cables?

Polyethylene is very economical and dielectrically hard to improve upon (teflon is slightly better, but its cost is far greater, and its flexibility is far from ideal). Its only drawback is a low melting point which requires a skilled touch with the soldering iron to avoid problems in production.

What does the electrostatic shield do?

As the cable is flexed and bent, the copper shield rubs against the insulation, generating static electricity. The electrostatic shield acts as a semi-conducting barrier between the copper shield and the center insulation which discharges these static electrical charges. Without it any movement of the cable would result in obnoxious “crackling” noises being generated.

What are electrostatic shields made of?

Electrostatic shields first appeared in cable as a layer of rayon braid. Nowadays carbon-impregnated dacron “noise-reducing tape” is a common element in any good high impedance cable. Conductive-plastic (carbon-loaded PVC) electrostatic shields have also become common. Conductive PVC is extrudable just like an insulation, which guarantees 100 percent coverage of the insulation with a very consistent thickness and a very low coefficient of friction.

The superior conductivity of C-PVC makes it much more effective than the semiconductive tape in bleeding off the small electrical charges that cause “the crackles.” Extruded C-PVC is also thinner and more flexible than dacron tape, which is applied longitudinally and restricts the “bendability” of the cable. Although conductive plastic (with a copper drain wire) has been used to completely replace copper braid or serve shields, its effectiveness falls off above 10 kHz.

Why are some cables microphonic?

As noted previously, the center conductor, insulation and shield of a coaxial cable form a capacitor; and, as many a microphone manufacturer will tell you, when the plates of a capacitor are deflected, a voltage is generated. (This is the basis of the condenser microphone!) Similarly, when the plates (conductor and shield) of our “cable capacitor” are deflected (for instance, by stepping on it or allowing it to strike a hard floor), a voltage is also generated.

Unfortunately, this voltage generally pops out of the amplifier as a distinct “whap,” and can be very hard on ears and loudspeakers alike. Effects of this type are called triboelectric noise.

How can cable noise be reduced?

The electrostatic shield’s charge-draining properties help greatly to diminish triboelectric effects. Triboelectric impact noise is also reduced by decreasing the capacitance of the cable with thicker and softer insulation because the deflection of the conductor is proportionally reduced. This is the main reason that the single-conductor coaxial configuration remains superior to the “twisted pair” for high-impedance uses—it allows thicker insulation for a given overall diameter.

Triboelectric effects are accentuated by high source impedances, and are at their worst when the source is an open circuit—for instance, a cable plugged into an amplifier with no instrument at the sending end. Testing for this type of noise requires termination of the cable with a shielded resistance to simulate the source impedance of a real instrument.